When precise fluid control is required at low flow rates, micro gear pumps stand out as a reliable and efficient solution. They offer stable output, compact size, and consistent performance even under varying pressure conditions. These features make them indispensable in applications such as analytical instruments, medical devices, and small-scale cooling systems. This article explores why micro gear pumps are particularly suited for low flow scenarios, highlighting their core advantages and common use cases.

Unique Features of Micro Gear Pumps

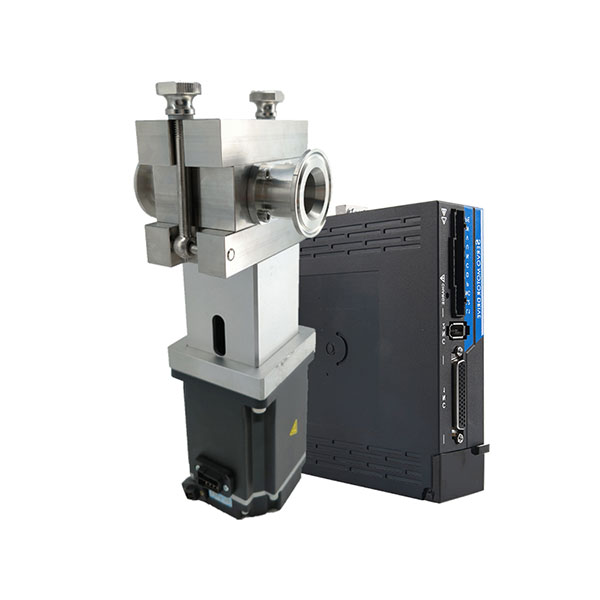

Compact and Lightweight Design

Micro gear pumps feature a compact design that allows them to fit into tight spaces. Their lightweight construction reduces the need for heavy support structures, making them ideal for portable and small-scale systems. Industries benefit from this design by integrating these pumps into equipment without compromising functionality or space efficiency.

Consistent and Precise Flow Rates

The gear pump mechanism ensures consistent fluid flow, even in demanding conditions. Micro gear pumps excel in precise dosing applications, delivering exact quantities of fluid with remarkable accuracy. This capability makes them indispensable in industries like pharmaceuticals and chemical processing, where precision is critical for maintaining product quality.

Low Pulsation and Leak-Free Operation

Micro gear pumps operate with minimal pulsation, ensuring smooth fluid delivery. Their design prevents leaks, enhancing reliability and reducing maintenance needs. This leak-free performance is particularly valuable in applications requiring contamination-free fluid transfer, such as medical devices and food processing systems.

Micro Gear Pumps VS Other Pump Types

Micro Gear Pumps vs. Centrifugal Pumps

Centrifugal pumps rely on high-speed impellers to move fluids, making them effective for high-flow applications. However, they struggle with low flow scenarios due to their inability to maintain consistent pressure at reduced flow rates.

A micro gear pump, on the other hand, excels in delivering precise and steady flow, even at minimal volumes. Its gear mechanism ensures accurate fluid transfer without the need for high-speed operation.

Additionally, centrifugal pumps often face challenges when handling high viscosity fluids. Their performance declines as fluid thickness increases, leading to inefficiencies.

In contrast, a micro gear pump is specifically designed to handle high viscosity liquids with ease. This capability makes it a preferred choice for industries requiring reliable performance in low flow and high viscosity applications.

Micro Gear Pumps vs. Peristaltic Pumps

Peristaltic pumps use a squeezing action to move fluids through flexible tubing. While effective for certain applications, they often produce pulsating flow, which can disrupt processes requiring smooth fluid delivery.

A micro gear pump eliminates this issue by providing a continuous, pulseless flow. This feature is particularly valuable in precision-driven industries like pharmaceuticals and food processing.

Durability is another factor where micro gear pumps outperform peristaltic pumps. The tubing in peristaltic pumps wears out over time, requiring frequent replacement.

In contrast, the robust design of a micro gear pump ensures long-term reliability with minimal maintenance. This durability reduces downtime and operational costs, making it a more efficient solution for low flow applications.

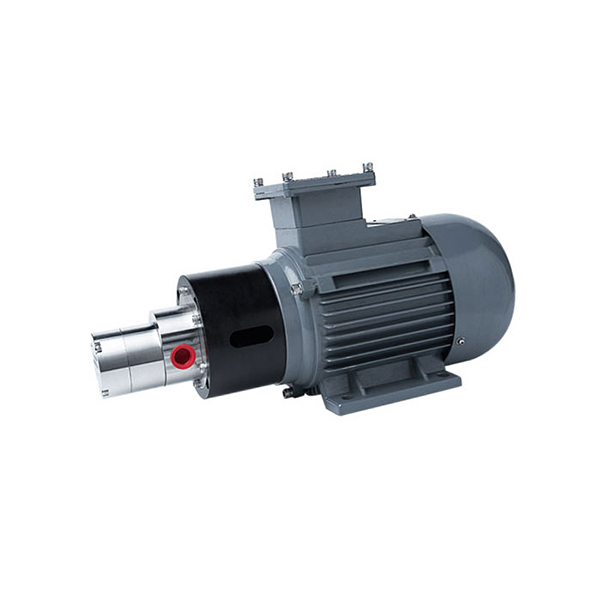

High Viscosity Pump Capabilities

Handling high viscosity fluids presents unique challenges for many pump types. Centrifugal and peristaltic pumps often struggle with thick liquids, leading to reduced efficiency and inconsistent flow.

A micro gear pump, however, is engineered to overcome these challenges. Its gear-driven mechanism generates the necessary force to move high viscosity liquids without compromising performance.

Industries such as cosmetics, adhesives, and lubricants benefit significantly from the high viscosity pump capabilities of micro gear pumps. These pumps ensure precise dosing and consistent flow, even when dealing with the thickest fluids. Their ability to maintain accuracy and reliability under such conditions highlights their superiority in demanding applications.

Benefits of Micro Gear Pumps for Low Flow Applications

Energy Efficiency and Cost Savings

Micro gear pumps optimize energy usage by delivering steady output without requiring high-speed operation. Their gear-driven mechanism minimizes energy consumption, making them ideal for low flow applications.

Industries benefit from reduced operational costs due to the pump’s efficiency and long-term reliability. The ability to handle high viscosity fluids without compromising performance further enhances cost-effectiveness.

Reduced Environmental Impact

The design of micro gear pumps supports sustainable practices by reducing waste during fluid transfer. Their precise dosing capabilities ensure accurate delivery, minimizing excess fluid usage.

Leak-free operation prevents contamination and protects the environment from harmful spills. By efficiently handling high viscosity liquids, these pumps contribute to cleaner and safer industrial processes.

Versatility Across Industries

Micro gear pumps excel in diverse applications, from medical dosing to the transfer of viscous liquids in cosmetics and adhesives. Their ability to handle high viscosity fluids makes them indispensable in industries requiring precise fluid control. The compact design allows integration into systems with limited space, while their steady output ensures consistent performance across various sectors.

Low Flow Applications of Micro Gear Pumps

In the pharmaceutical industry, micro gear pumps ensure precise dosing of medications and chemicals. Their gear pump mechanism provides smooth and accurate fluid transfer, which is essential for maintaining the quality of sensitive formulations.

In food and beverage industry, micro gear pumps excel in transferring viscous fluids like sauces, syrups, and oils. Their leak-free operation ensures contamination-free processes, which is vital for maintaining hygiene standards. Additionally, their compact design allows seamless integration into automated production lines.

In the cosmetics industry, micro gear pumps handle high viscosity liquids such as creams, lotions, and adhesives. Their high viscosity pump capabilities ensure precise dosing and consistent flow. This precision reduces waste and enhances product quality.

Laboratories and research facilities also rely on micro gear pumps for low flow applications. These pumps provide accurate fluid delivery for experiments and testing, ensuring reliable results.

Cconclusion

Micro gear pumps deliver unmatched precision and reliability for low flow applications. Their gear pump mechanism ensures consistent fluid transfer with minimal pulsation. This efficiency reduces waste and enhances performance across industries. The leak-free design and energy-saving operation make them a versatile and sustainable choice for accurate fluid handling.