Handling dangerous liquids is a complex and rigorous process in most industries. Chemical manufacturing, crude oil processing, and water treatment are some of the industries which require equipment for handling dangerous liquids safely, effectively, and reliably.

There are various technologies available, but magnetic drive gear pumps are a top option for handling dangerous liquids. In this blog, we will look at the qualities, features, and uses of magnetic drive gear pumps to understand why they are a popular choice in industrial processes.

What are Magnetic Drive Gear Pumps?

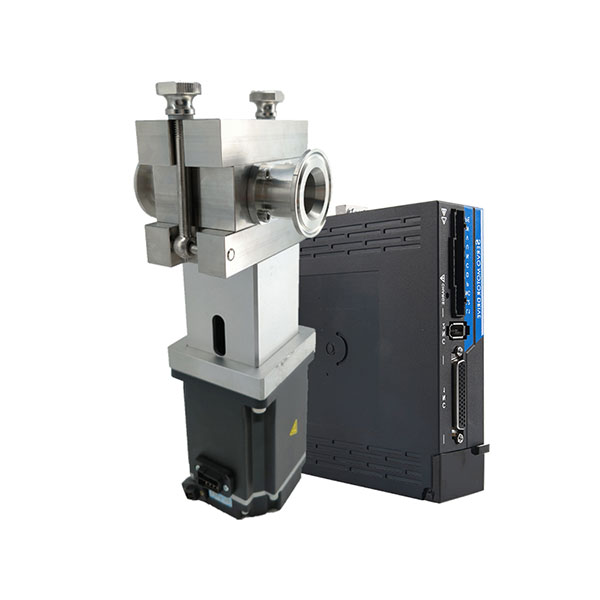

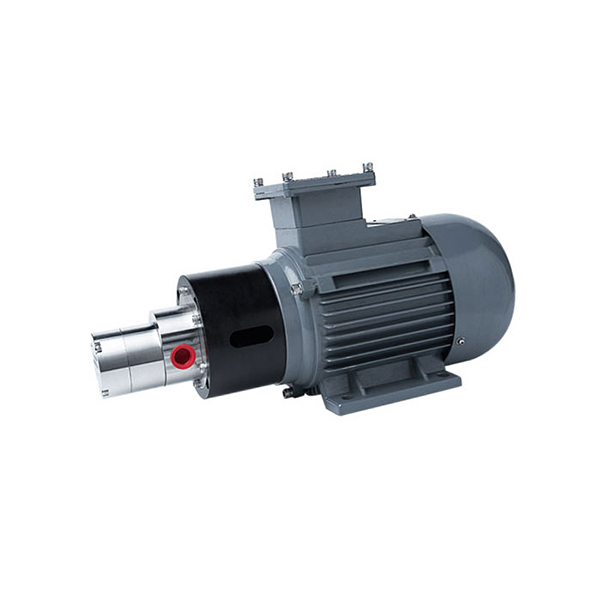

Magnetic drive gear pumps are specifically designed to move fluids with no mechanical seal. They utilize a magnetic coupling mechanism to prevent contact between the motor and the fluid being pumped. This greatly prevents any leaks from taking place, thereby making them highly suitable to deal with hazardous and toxic fluids.

In these pumps, the driving magnet is mounted on the motor shaft, and the driven magnet is mounted on the impeller or pump gear. The two magnets are separated inside a containment shell so that the pumped fluid is inside the pump.

The Problems of Handling Hazardous Fluids

Toxic liquids pose unique problems that need to be considered carefully:

- Toxicity: Most dangerous liquids are toxic and may cause harm to workers or the environment if improperly handled.

- Flammability: Certain liquids and chemicals are highly flammable, hence a hazard to be used.

- Corrosiveness: Power liquids such as acids and alkalis have the power to ruin equipment and tools after a while.

- Volatility: Some liquids vaporize easily, thus resulting in spills or contamination of air.

- Regulatory Guidelines: Companies need to stick to tough safety laws in order to properly manage harmful products.

Because of these issues, it is necessary to use gear that lessens risks and improves fluid movement.

Key Characteristics of Magnetic Drive Gear Pumps

-

Leak-Free Operation

Mechanical seals wear out and will begin to leak after a period of time. Mag-drive pumps are seal-less, however, and use a magnetic coupling. This renders their operation leak-free, a significant factor when working with hazardous fluids.

-

Corrosion-Resistant Materials

Magnetic drive pumps are usually made of quality materials like stainless steel, polypropylene, or other corrosion-resistant plastics. This makes them the right option for pumping harsh chemicals such as acids, solvents, and alkalis.

-

Lightweight Design

Mag-drive pumps are small and lightweight that need less care than normal pumps. They are built to run easily, even in harmful industrial environments.

-

High-Temperature and Pressure Handling

These pumps are also able to handle fluids at high pressure and high temperature and are, therefore, appropriate for various applications.

-

Dry-Run Protection

High-capacity magnetic drive pumps can include dry-run protection to prevent damage if the pump is allowed to dry out.

Benefits of Magnetic Drive Gear Pumps for Hazardous Liquids

-

Improved Safety

The leak-free operation of magnetic drive pumps notably improves safety in applications where hazardous fluids are being processed. Workers are protected from toxic vapors, and spills are minimized.

-

Environmental Protection

By reducing leaks and spills, mag-drive pumps limit environmental contamination. This is very important in industries with strict environmental rules.

-

Reduced Maintenance Expenses

There is less wear and tear on the pump components without mechanical seals. This reduces maintenance costs and increases the life of the pump.

-

Energy Efficiency

Magnetic drive pumps are the most energy-efficient. Low energy consumption is ensured by smooth operation, and hence, they are cost-effective in the long run.

-

Compliance with Regulations

Businesses dealing with hazardous liquids must comply with safety and environmental standards. Mag-drive pumps enable businesses to remain compliant with reduced leak and spill risks.

Applications of Magnetic Drive Gear Pumps

Magnetic drive pumps are usually found in most industries for specific purposes:

1. Chemical Production

Magnetic drive gear pumps supply harmful chemicals like acids, caustics, and solvents in chemical plants. They offer corrosion-resistant operation that is safe and reliable.

2. Oil and Gas Industry

The petroleum and gas industry needs pumps to handle flammable and toxic fluids. Magnetic drive pumps are right for application in hydrocarbon transport, additives, and other chemicals used in refining.

3. Pharmaceutical Industry

In the pharmaceutical production process, a sterile and leak-free environment must be maintained. Active drugs and solvents are transported safely by mag-drive pumps.

4. Water Treatment Plants

Magnetic drive pumps are used in water treatment plants to treat chlorine, sulfuric acid, and other chemicals used in the purification process.

5. Food and Beverages Industry

Although in such situations, attention is generally drawn to non-hazardous liquids, mag-drive pumps are utilized to operate sanitizers and cleaning chemicals that must be treated with care.

Things to Keep in Mind When Choosing a Magnetic Drive Gear Pump

When choosing a magnetic drive pump for dangerous fluids, keep in mind the following:

-

Material Compatibility

Make sure the materials used in the pump are compatible with the fluid being pumped. For example, corrosive fluids should be pumped using corrosion-resistant materials.

-

Flow Rate and Pressure Requirements

Select a pump that will deliver your required flow rate and pressure requirement for your application.

-

Temperature and Viscosity

Take into consideration the viscosity and temperature of the fluid in order to efficiently pump the fluid.

-

Certifications and Standards

Look for pumps that are industry standard and certified to ensure reliability and safety.

Conclusion

Magnetic drive gear pumps are the best pumps for handling hazardous fluids since they have a leak-free operation, resistance to corrosion, and low maintenance. They offer greater security, environmental protection, and energy efficiency and are, therefore, an excellent choice for businesses handling toxic, flammable, or corrosive liquids.

By investing in excellent quality and reliable mag-drive pumps, companies can ensure the safe and efficient processing of hazardous fluids while meeting strict regulation standards. If your company is dealing with hazardous fluids and you desire a safe, efficient, and cost-effective option, magnetic drive gear pumps are your best choice.