Magnetic drive pump systems raise technology to a new level, becoming an indispensable component of modern fluid systems. It is their unique sealless design that ensures accurate, leak-free operation. This makes them ideal for environments where contamination, maintenance, and space are major concerns.

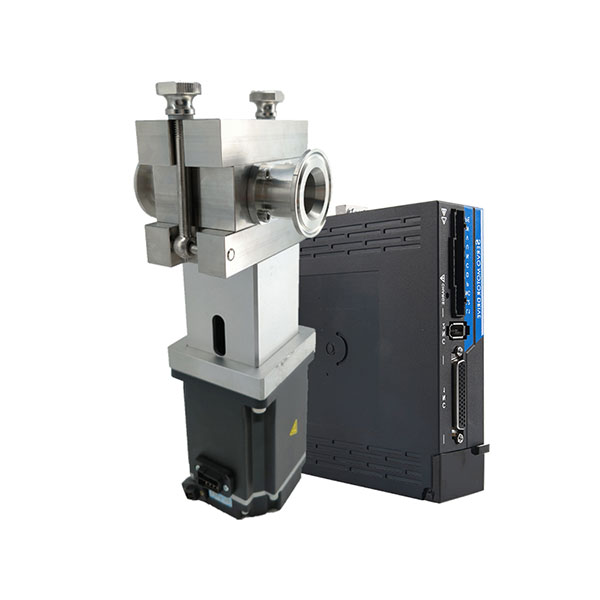

In the case of the micro gear pumps manufactured by CHENHUI, magnetic drive technology allows the controlled and efficient transfer of small volumes of fluid. This is ideal for sectors that need precise dosing and clean fluid delivery.

This article analyzes the practical uses of magnetic drive pumps, focusing on micro applications, especially where CHENHUI’s compact and efficient technology is applicable.

What Are Magnetic Drive Pumps?

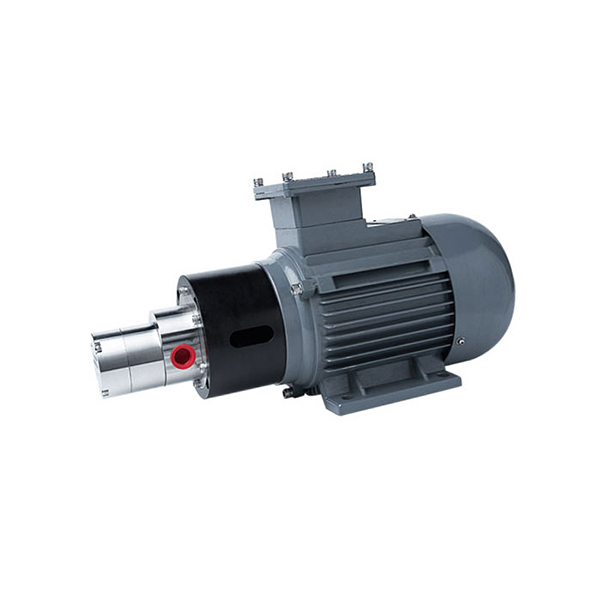

Magnetic drive pumps work by using a magnetic coupling system in place of traditional shafts. The external motor drives a magnet that is connected to an internal magnet situated within a pump. The internal magnet drives the pump`s impeller. This design removes the need for shaft seals, which are often the weakest components in traditional pumps.

Since there are no physical links between the impeller and the motor, therefore, there is no possibility of fluid leaking through damaged seals. This provides strong protection for sensitive, hazardous, or valuable fluids, particularly in systems where precise, contamination-free operation is needed.

Key Features of Micro Magnetic Drive Pumps

Micro Magnetic drive pumps have various sizes, but CHENHUI is known for making micro gear models that specialize in low fluid flow precision transfers. Their most notable characteristics are the following:

- Sealless Design: It reduces the possibility of leakage and cross-contamination.

- Compact Footprint: Great for space-constrained installations and portable devices.

- Low Flow, High Precision: Able to provide micro volumes of fluids with extreme precision.

- Quiet, Vibration-Free Operation: It is suitable for medical, laboratory, and analytical work.

- Corrosion Resistance: Components like stainless steel or engineered plastics are common due to their compatibility with aggressive fluids.

Uses of Magnetic Drive Pumps in Different Industries

Now, let us examine the most important industries and uses of magnetic drive micro gear pumps:

1. Pharmaceutical And Medical Devices

Clean handling and precision dosing are mandatory for pharmaceutical laboratories and diagnostic devices. Magnetic drive micro pumps target the following areas:

- Automation of liquid reagent transfers.

- Fluid circulation in dialysis or IV systems.

- Controlled measurement of active components in the formulation of medications.

Their leak-free nature guarantees that there is no contamination during fluid transfer, which ensures patient safety and the integrity of drugs.

2. Analytical and Laboratory Equipment

Consistency is important for measurement systems like chromatography, spectrometry, and sample preparation tools in laboratory tests. They:

- Provide precision and repeatability in the dosing.

- Achieve silence while operating in sensitive environments.

- Resist bombardment by chemically aggressive solvents.

Because of magnetic drive technology, metal-on-metal friction is eliminated, and therefore, shedding of particles and contamination is greatly reduced.

3. Semiconductor and Electronics Manufacturing

Semiconductors require ultra-pure chemicals to prevent damage to delicate chips. This ensures that they are treated without any impurities that could cause damage. Therefore, magnetic drive pumps are used to:

- Transfer etching agents, coolants, and resist materials.

- Safely manage corrosive liquids of high purity or high grade.

- Ensure no loss of liquids in closed-loop fluid systems.

The compact size of the pumps is advantageous in automated systems for wafer cleaning and deposition.

4. Printing and Inkjet Systems

Hygienic ink dispensers must be free from any blocking that prevents access to dispense inks. Micro magnetic drive pumps allow:

- Inks are pushed out with no spikes in pressure.

- Special inks or coatings are handled gently.

- Drying, backflow, and air contamination are avoided.

They are so small that they can be placed directly into the printers and other printer parts.

5. Food & Beverage Dosing

Micro magnetic drive pumps are not designed to work with food materials, particularly those that contain solid and particulate matter, but they are suitable for:

- Spraying or pouring flavoring, coloring, or vitamin supplements.

- Transferring cleaning or sanitizing fluids.

- Exchanging and circulating ingredients in closed systems.

The preventive measures help avoid the loss of ingredients and ensures compliance with regulations.

6. Fuel Cells and Battery Systems

Energy research and battery manufacturing rely on accurate fluid management of several processes for performance and safety. Mag-drive micro pumps are used for:

- Fuel cells’ electrolyte circulation.

- Additive or coolant dosing within battery packs.

- Chemically resistant closed-loop fluid systems.

The Advantages of Magnetic Drive Pumps over Conventional Pumps

Now, let us analyze the reasons why magnetic drive systems are gaining preference over seal-based systems among engineers and designers, particularly for precision applications.

| Feature | Magnetic Drive Pump | Traditional Pump |

| Seal-Free Design | No leakage | Prone to seal wear |

| Maintenance Frequency | Low | High |

| Chemical Compatibility | Excellent with the right materials. | Depends on the sealing material. |

| Compressibility | Ultra compact versions exist. | Bulkier, less integration. |

| Controlled Precision Flow | Ideal for microfluidic tasks. | Externally controlled most of the time |

Things to Consider Before Use

Despite the numerous merits of magnetic drive micro pumps, they do present a set of challenges that users must prepare for.

- No solids: These pumps are designed for particle-free clean fluids only.

- Dry run avoidance: Internal components can be damaged or overheat due to excessive coolant-less running.

- Remember the limits of magnet temperatures: Demagnetization can occur from overheating.

- Be familiar with the viscosity of your fluid: Unless the pump is rated for it, extremely thick fluids may hinder performance.

Properly matching a pump to a specific type of fluid, flow rate, and operational temperature will yield the best results in performance with the longest service life.

Conclusion

Magnetic drive pumps stand out due to their compact dimensions and their ability to work with aggressive chemicals, which makes them suitable for use in medical and electronic industries as well as in chemical dosing applications where precision is a must.

CHENHUI is a manufacturer of magnetic drive pumps focus on safe, accurate, and reliable fluid transfer in challenging conditions where failure is unacceptable. If you are building a diagnostic device or a lab automation system, these pumps will ensure that you achieve repeatable and dependable clean results.