When it comes to positive displacement pumps, gear pumps are often the first choice for many industries. They can deliver a steady, accurate flow . But what exactly makes gear pumps so popular? This article will explore positive displacement gear pump working principles, key benefits, and why they remain a preferred option in fields like chemical processing, lubrication, and food production.

What is positive displacement pumps?

Positive displacement refers to a design where the pump moves a fixed volume of fluid with each cycle or rotation. Unlike centrifugal pumps, which rely on velocity to push fluid and vary flow with pressure changes, positive displacement pumps deliver a consistent flow regardless of pressure.

In simple terms, each turn of a positive displacement pump traps and pushes a set amount of liquid forward. This ensures precise and steady flow rates, making these pumps ideal for applications requiring accuracy and reliability.

Positive displacement pumps handle viscous fluids well and maintain flow under high pressure. Common types include gear pumps, piston pumps, and diaphragm pumps, all designed to move fluid by mechanically trapping and displacing it.

Key Benefits:

- Highly efficient under different pressures and viscosities.

- Compact size accommodates space-limited applications.

- Low maintenance because of fewer parts that move.

How Does it Work?

- Fluid Intake: The pump contains a chamber that has a volume that increases to accept fluid.

- Trapping the Fluid: The pump mechanism (e.g., gears, pistons, or diaphragms) encloses a definite volume of fluid.

- Displacement: The pump decreases the chamber volume, pushing the fluid out at a steady rate.

- Continuous Flow: This process is repeated to provide a continuous flow of fluid irrespective of pressure fluctuations.

Types of Positive Displacement Pumps

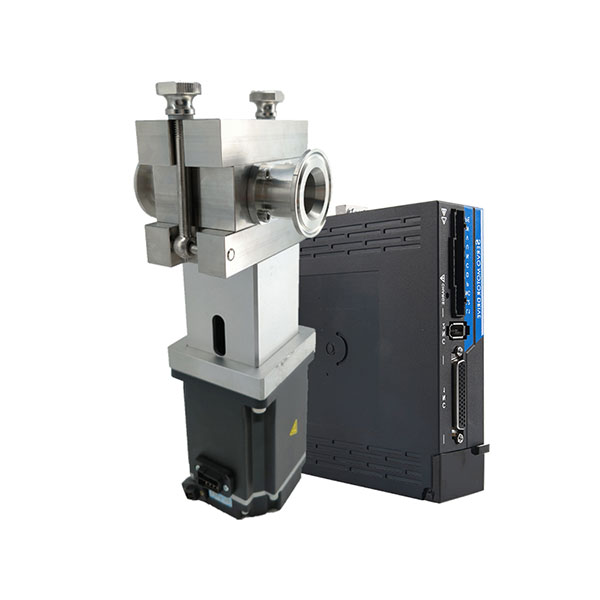

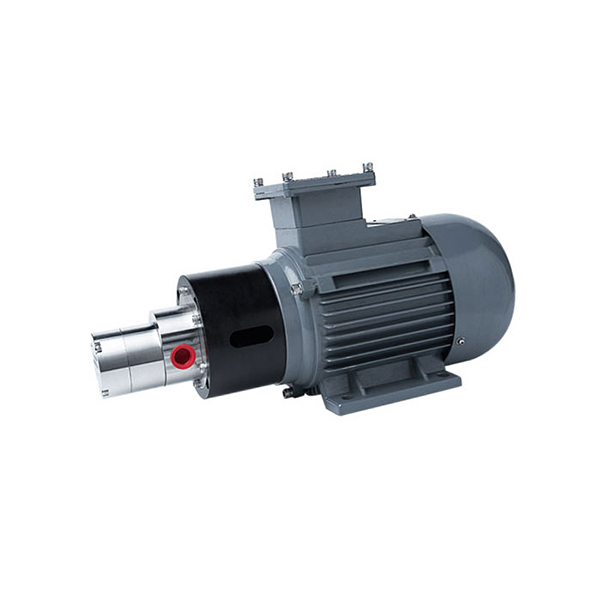

Gear Pumps

Gear pumps use two rotating gears to trap fluid between the gear teeth and the pump housing. As the gears turn, the fluid is pushed forward in a steady, fixed volume. These pumps are best for clean, non-abrasive, and lubricating liquids such as oil, fuel, or chemicals.

Because of their precise and repeatable flow, gear pumps are widely used in chemical dosing, lubrication systems, and microfluidic equipment where accurate volume control is critical.

Piston Pumps

Piston pumps move liquid by pushing a piston back and forth inside a cylinder. When the piston retracts, it draws fluid in; when it moves forward, it forces fluid out. This mechanism can generate very high pressure and provides accurate flow rates.

Piston pumps are suitable for clean fluids that don’t contain particles and are commonly used in industrial machinery, metering systems, and hydraulic equipment. However, they require tight sealing and regular maintenance to avoid wear.

Diaphragm Pumps

Diaphragm pumps use a flexible rubber or plastic membrane that moves back and forth to draw in and push out fluid. The fluid stays inside a fully sealed chamber and never touches the pump’s moving parts.

This design makes diaphragm pumps ideal for corrosive, toxic, or abrasive liquids. They are commonly used in chemical transfer, wastewater treatment, and medical dosing, where safety and fluid isolation are essential.

Benefits of Gear Pumps in Positive Displacement Applications

- Accurate and Consistent Flow: Gear pumps deliver a fixed fluid volume per rotation, ensuring precise flow control regardless of pressure changes.

- Handles High Viscosity Fluids: Ideal for pumping thick liquids like oils, syrups, and resins without losing efficiency.

- Stable Flow Under Pressure Variations: Maintains steady flow rates even with fluctuating system pressure, perfect for hydraulic and closed-loop systems.

- Compact and Space-Saving Design: Simple mechanical structure allows easy integration into tight spaces and mobile equipment.

- Smooth, Low-Pulsation Output: Provides continuous, nearly pulse-free flow to protect downstream components from wear and damage.

- Low Maintenance and Reliable: Fewer moving parts and self-priming operation reduce downtime and maintenance costs.

Applications of Positive Displacement Gear Pumps

Positive displacement gear pumps are widely used across various industries because of their reliable flow control and ability to handle a range of fluid types. Their versatility and precision make them a top choice for many demanding applications.

- Chemical Industry: Accurate dosing and transfer of solvents, acids, and lubricants. Resistant to corrosive fluids.

- Lubrication Systems: Steady lubrication flow in machinery and vehicles. Compact for tight spaces.

- Food and Beverage: Sanitary pumps for oils, syrups, and flavorings. Ensure contamination-free, consistent flow.

- Paints and Coatings: Handle thick fluids like paints and adhesives. Provide uniform flow and reduce waste.

- Pharmaceutical and Medical: Precise dosing of medical fluids and reagents. Prevent contamination.

Conclusion

Gear pumps stand out as a practical and dependable solution for positive displacement needs. They provide consistent flow under different pressures and viscosities while requiring minimal maintenance. Because of these qualities, gear pumps remain a go-to option in many industries where stable and accurate fluid control is necessary.

FAQs

1. What does positive displacement mean in pumps?

Positive displacement means the pump moves a specific volume of fluid with each cycle. It traps fluid in a chamber and forces it out. This leads to a steady, predictable flow that does not change much even if the pressure varies.

2. Is a gear pump a positive displacement pump?

Yes, a gear pump is a positive displacement pump. It works by trapping a fixed amount of fluid between its gears and moving it from the inlet to the outlet. This means the pump delivers a consistent volume of fluid with each rotation, no matter the pressure.

3. What factors determine the displacement of a gear pump?

The displacement of a gear pump depends mainly on the size of the gears and the space between them. Larger gears or more teeth carry more fluid. The width of the gears and the distance between the pump casing and gears also affect how much fluid is moved each turn.

4. How does a positive displacement gear pump operate?

In a positive displacement gear pump, two gears mesh together inside the casing. As the gears turn, they create spaces that trap fluid at the inlet side. The fluid is carried around the gears and pushed out on the outlet side. The tight fit prevents fluid from flowing backward.

5. What are the differences between centrifugal pumps and positive displacement pumps?

Centrifugal pumps use a spinning impeller to push fluid outward by centrifugal force. Their flow varies with pressure changes. Positive displacement pumps, like gear pumps, move a fixed amount each cycle. They work better for high-pressure, low-flow tasks, while centrifugal pumps suit high-flow, low-pressure needs.