One common question when picking a pump for the setup is: what is the difference between brushless and brushed pumps? This is a major question, especially when working with compact, true, and low-maintenance fluid systems. These pumps may look similar, but their applications and advantages differ depending on the purpose. We’ll examine how these pumps function, what makes them special, and which one might be best for you in this blog.

Understanding Brushed Pumps

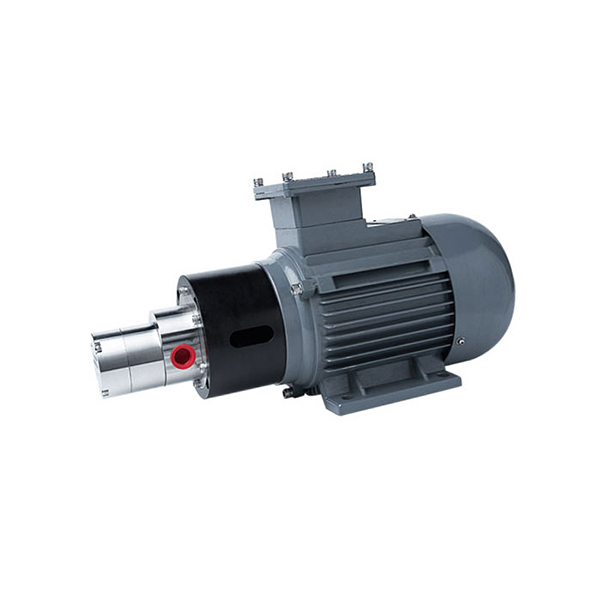

Brushed pumps run on traditional brushed DC motors. Many industries still use these motors, which have been around for forever. The term “brushed” refers to the tiny carbon brushes that come into touch with the commutator, a rotating part inside the motor.

How Brushed Pumps Work:

The brushes in the motor apply pressure on the switch, which is attached to the rotor. The magnetic field forces the rotor to spin when electricity goes through. The solution is moved through the system by this rotating motion, which also drives the pump.

Pros of Brushed Pumps:

- Simple and inexpensive: These pumps are easy to produce and purchase.

- Easy to regulate: Speed and flow rate are easily controlled using simple electronics.

- Well-documented technology: They have been around long enough that they’re simple to repair and replace.

Cons of Brushed Pumps:

- Wear and tear: The brushes rub against the commutator and wear down over time.

- Shorter lifespan: Because of friction, these pumps usually don’t last as long.

- More maintenance: Brushes need to be replaced regularly.

Brushed pumps are often used in applications where cost is a bigger factor than durability or where the pump is only used occasionally.

Understanding Brushless Pumps

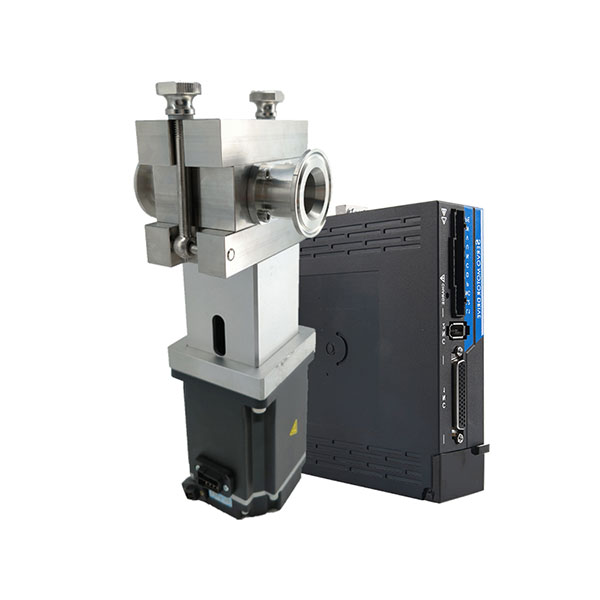

Now, let’s look at brushless pumps. These make use of brushless DC motors, sometimes known as BLDC motors, which are brushless. They use magnets and electronic circuits to drive the motor and produce rotation.

Brushless Pump Operation:

Electronic controllers and permanent magnets are used in brushless motors. Coils inside the motor receive signals from the controller, which generates an attractive field that rotates the rotor. There is less wear and friction because there are no brushes in direct touch.

Pros of Brushless Pumps:

- Longer lifespan: Brushless motors have a far longer lifespan because they don’t have any brushes to break out.

- Silent operation: They produce less noise and operate better.

- High efficiency: They are effective since less energy is lost as heat.

- Low maintenance: No brushes means fewer parts that need replacing.

Cons of Brushless Pumps:

- Higher cost: They are more expensive to produce.

- More complicated: They require electronic controllers, which can be harder to fix in the event that they break.

For continuous use, small places, and settings where efficiency and noise reduction are serious such as labs, medical devices, or small electronics, brushless pumps are perfect.

Important Distinctions Between Brushed and Brushless Pumps

The main difference between these two types of pumps is the kind of motor they use. Brushed pumps use physical brushes that touch moving parts to create motion. Brushless pumps use electronic signals and magnets to create motion without contact. This single change leads to many differences in how the pumps perform. Let’s look at what is the difference between brushless and brushed pumps.

Here’s a simple breakdown:

| Feature | Brushed Pumps | Brushless Pumps |

| Motor Type | Uses brushes and a commutator | No brushes; uses electronic controller |

| Lifespan | Shorter due to wear | Longer due to no friction |

| Noise | Louder due to brush contact | Quieter, smoother operation |

| Maintenance | Requires regular maintenance | Almost maintenance-free |

| Efficiency | Lower | Higher |

| Cost | Less expensive | More expensive |

| Best For | Short-term or cost-sensitive projects | Long-term, reliable applications |

Which One Should You Choose?

As per your needs, you can select between brushed and brushless pumps. A brushed pump can be suitable if you’re looking for something affordable for light usage. But a brushless pump is a better option if you need a pump that works often and lasts longer. Being aware of ”what is the difference between brushless and brushed pumps” makes it easier to pick the right one for your needs.

It’s also important to note that brushless pumps are more advanced and more popular in modern uses. They are becoming more common in high-tech industries because they provide a reliable, quiet, and efficient solution for long-term use.

CHENHUI offers a full range of reliable and durable magnetic drive micro gear pumps with customizable options for both brushed and brushless motors, giving users the flexibility to match different system requirements. Whether you’re looking for a brushed or a brushless pump that offers precise speed regulation and long-term stability, our solutions are built for systems that demand accuracy, low maintenance, and long service life.

Key Use Cases

Let’s quickly go over some of the common uses for each type of pump to give you a clearer idea of where each one fits.

Brushed Pump Applications:

- Toys or hobby machines

- Low-cost aquarium pumps

- Occasional-use cooling systems

Brushless Pump Applications:

- Medical devices

- Computer cooling systems

- Small water features

- Electric vehicles

- Laboratory equipment

In systems that need steady, long-term operation with minimal noise and vibration, brushless pumps shine. If you only need the pump for light or intermittent use and your budget is tight, brushed pumps are worth considering.

Final Thoughts

So, what is the difference between brushless and brushed pumps? It comes down to how they’re powered and how they wear over time. Brushless pumps use electronic control with no physical contact, making them last longer, run still, and perform more efficiently. Brushed pumps are simpler and cheaper but need more maintenance and don’t last as long.

Consider your system’s needs when choosing between the two, including how frequently it will operate, how much noise you can accept, and if you want to forgo regular service.

At CHENHUI , we offer premium brushless and brushed micro gear pumps designed for compact systems and efficient fluid transfer. Whether you choose a micro gear pump with a brushed motor for cost-effective, low-duty applications, or a brushless motor for high-performance, CHENHUI guarantees you consistent performance supported by expert engineers and attention to detail.