Like other pumps, magnetic drive pumps have their astonishing applications, such as lab automation, chemical dosing, and fluids in pharmaceutical processes. In these scenarios, a great manufacturer is crucial for the overall success of a business. With proper precision, chemical resistance, and leak-free fluid handling, the magnetic drive pump system can perform even better.

This article outlines the essential advantages of magnetic drive pumps, what key manufacturers normally provide, and how to assess and make a selection, including a highlight on three key magnetic drive pump manufacturers.

An Overview of Magnetic Drive Pumps

A magnetic drive pump uses magnetic coupling in a sealless design to transfer torque from the motor to the impeller. It does not need a shaft connection. This design eliminates seals entirely, which means the common mechanical shaft seal with its numerous failure points is absent, and in turn reduces the risk of leak, contamination, or removal of fluid.

A magnet attached to the motor turns another magnet inside the sealed pump. This magnetic connection spins the impeller without needing a traditional seal. Because of this, the liquid stays completely enclosed and can’t leak out.

Mag-drive pumps are very popular for applications such as:

- Safe handling of corrosive fluids and hazardous materials.

- Dosing and metering with great precision.

- Low-flow precision, especially micro gear pumps.

- Space-saving designs for Original Equipment Manufacturer integration.

Key Benefits of Magnetic Drive Pumps

- Leak-Proof Functionality: The absence of mechanical shaft seals eliminates the primary source of leakage. This is important for dealing with toxic, flammable, or high-purity fluids. The sealed system design guarantees a hermetic barrier that protects the surrounding environment and the system components.

- Low Maintenance Requirements: Magnetic drive pumps require less maintenance than other pumps due to their lack of seals. This pump does not need any complex system seal maintenance, breakdown maintenance, or rotor replacements. This leads to reduced downtime and increased operational lifespan, indirectly reducing total operational cost.

- Safety Improvement: Mag-drive systems assist in meeting safety and compliance regulations in personnel and infrastructure protection. It is important for industries handling aggressive chemicals, flammable solvents, and radioactive fluids because of their leak-proof nature.

- Energy Efficiency: Many micro magnetic drive pumps use brushless DC motors, which have more flow control and consume less power. The sealless design reduces friction, improving efficiency along with the power-saving features.

- Long Service Life: Durability is one of the key attributes in the design of mag-drive pumps. Quality performance for a long duration, even under harsh conditions, is possible due to the high-grade materials (PTFE, stainless steel, and ceramics) and reduced exposed moving parts.

What Magnetic Drive Pump Manufacturers Offer?

1. High Quality Material Selection

Magnetic drive pump manufacturers carefully select materials to ensure durability and performance. For example, pump bodies are often made from 316L stainless steel, prized for its excellent corrosion resistance and strength. Gears may use PEEK, a high-performance polymer that handles wear well。

Shafts can be made from materials like 316L stainless steel, ceramic, tungsten steel, or titanium alloy. Each shaft material offers unique benefits—ceramic provides exceptional hardness and chemical resistance, tungsten steel adds toughness for heavy-duty use, and titanium alloy offers strength with lightweight corrosion resistance.

2. Custom Pump Configurations

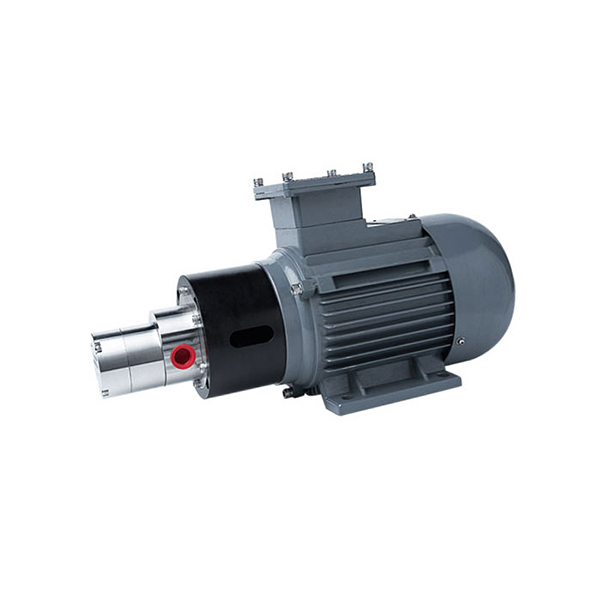

Manufacturers offer a variety of pump configurations to meet different needs. For example, magnetic drive pumps can use motors without brushes, which reduces wear and extends motor life, making them ideal for continuous operation. Bushed pumps, on the other hand, have bushings that provide simple and reliable bearing support, often preferred for certain cost-sensitive applications.

Regarding power, pumps can come with either AC (alternating current) or DC (direct current) motors. AC motors are common in fixed installations with stable power supplies, while DC motors offer precise speed control and are favored in portable or battery-powered systems.

Besides these, manufacturers allow customization of flow rates, pressure ranges, and sizes, ensuring the pump fits perfectly into your specific setup.

How to Choose the Right Magnetic Drive Pump Manufacturer?

Choosing a reliable magnetic drive pump manufacturer is a critical decision that directly impacts your operation’s efficiency, safety, and costs. A poorly chosen supplier can lead to frequent pump failures, increased maintenance expenses, and costly production downtime. To avoid these risks, focus on these essential criteria:

- Experience and Reputation

Choose manufacturers with proven experience in magnetic drive pump production. A solid track record ensures better product quality and reliability. - Wide Product Range and Customization

Look for manufacturers offering a wide range of pump models and customization options to fit specific flow rates, pressures, and fluid types. - Certifications and Quality Standards

Verify if the manufacturer complies with industry certifications like ISO. Certified products guarantee safety, durability, and consistent performance. - After-Sales Support and Technical Assistance

Opt for manufacturers who provide prompt customer service, technical support, and fast spare parts delivery to minimize downtime. - Competitive Pricing with Value

Avoid choosing solely based on price. Invest in manufacturers that balance cost with quality and service for long-term savings.

Top Magnetic Drive Pump Manufacturers to Choose

1. Micropump

Micropump, established in 1960, is a leading manufacturer known for developing magnetic drive pump technology. Its products include external gear pumps and matching motors, mainly used in printing, medical, and industrial applications.

The company operates a fully integrated facility in American factory, handling all manufacturing, assembly, and quality control. Micropump has maintained long-term production stability and technical consistency. Global sales are supported by offices in Europe and Asia, along with a network of distributors.

2. CHENHUI

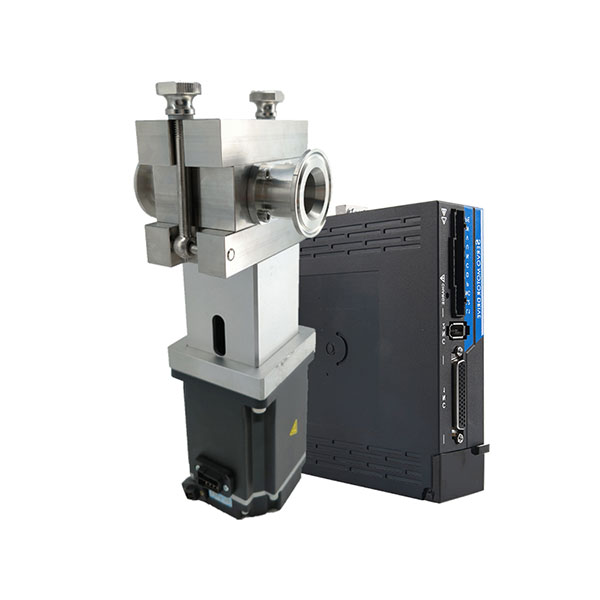

CHENHUI is a China manufacturer of micro external gear pumps featuring advanced magnetic coupling technology. Made from high-quality materials such as PEEK, stainless steel, and ceramics, their pumps ensure reliable performance and long service life.

Designed for precise and stable fluid handling across various industries, Chenhui provides magnetic drive micro gear pumps or pumps equipped with motors. Customization service is avaliable to meet specific needs. The company emphasizes durability and cost efficiency, backed by ongoing technical support to help customers optimize their applications.

3. DIENER Micro Pumps

DIENER is an OEM manufacturer of magnetic drive gear pumps and metering pumps. Its factory is located in Switzerland. Their pumps are widely used in medical diagnostics, analytical instruments, and industrial automation, where accuracy, repeatability, and reliability are critical.

Diener’s pumps provide precise volumetric control and long-term stability, and are made from materials resistant to corrosive chemicals. The company focuses on custom-engineered solutions.