Regular maintenance plays a vital role in ensuring magnetic drive micro gear pumps operate efficiently. Neglecting upkeep leads to reduced performance and costly repairs. Cleaning components, inspecting for wear, and addressing minor issues promptly help maintain magnetic drive gear pump reliability. These practices extend the pump’s lifespan while preventing unexpected breakdowns.

Importance of Regular Maintenance

Ensuring Optimal Performance

Regular maintenance ensures magnetic drive micro gear pumps operate at peak performance. Cleaning internal components and removing debris prevent blockages that could hinder flow rates. Monitoring operating conditions, such as pressure and temperature, helps identify inefficiencies early. These practices allow the pump to deliver consistent and reliable results, even under demanding conditions.

Preventing Costly Repairs

Neglecting maintenance often leads to expensive repairs. Worn-out parts, such as bearings or gears, can cause significant damage if left unchecked. Routine inspections help detect wear before it escalates into a major issue. Replacing small components promptly reduces the risk of catastrophic failures, saving both time and money.

Extending Pump Lifespan

A well-maintained magnetic drive gear pump lasts significantly longer than one that is neglected. Lubricating moving parts and ensuring proper alignment minimize unnecessary strain on the system.

Regular maintenance also prevents overheating, which can degrade materials over time. By addressing minor issues proactively, operators can maximize the lifespan of their pumps and reduce downtime.

Key Maintenance Practices

Cleaning and Inspection

Cleaning and inspecting magnetic drive micro gear pumps regularly is essential for maintaining their efficiency. Operators should remove debris and sediment from internal components to prevent blockages that could disrupt flow.

Visual inspections help identify early signs of wear, corrosion, or damage. Using a soft brush or non-abrasive tools ensures that delicate parts remain intact during cleaning. Consistent cleaning and inspection routines improve pump performance and reduce the likelihood of unexpected failures.

Monitoring Bearings and Wear

Monitoring bearings and other wear-prone components is critical for the longevity of magnetic drive gear pumps. Bearings endure significant stress during operation, making them susceptible to wear over time.

Operators should check for unusual noises, vibrations, or heat, as these often indicate bearing issues. Replacing worn bearings promptly prevents further damage to the pump’s internal mechanisms. Regular monitoring also ensures that the pump operates smoothly and efficiently under varying conditions.

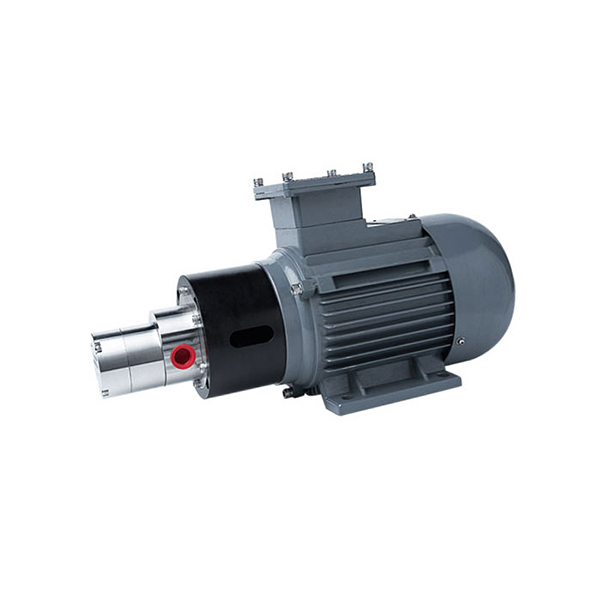

Fluid Compatibility and Avoiding Dry Runs

Ensuring fluid compatibility is vital to protect magnetic drive micro gear pumps from damage. Operators must verify that the pumped fluid does not react with the pump’s materials. Incompatible fluids can cause corrosion, swelling, or degradation of internal components.

Additionally, avoiding dry runs is crucial, as running the pump without fluid can lead to overheating and severe damage. Installing sensors to detect fluid levels helps prevent dry runs and safeguards the pump’s performance.

Proper Installation and Alignment

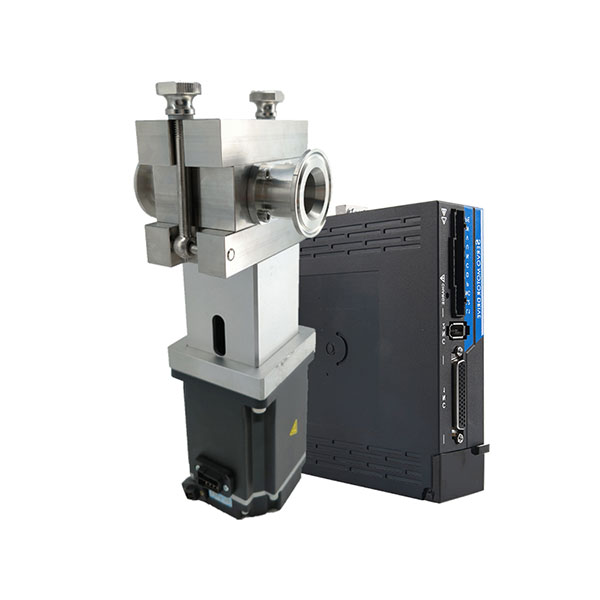

Proper installation and alignment play a significant role in the reliable operation of magnetic drive gear pumps. Misalignment during installation can cause excessive strain on the pump’s components, leading to premature wear.

Operators should use precision tools to ensure accurate alignment of the pump and motor shafts. Following the manufacturer’s guidelines for installation minimizes the risk of operational issues. A well-aligned pump operates more efficiently and experiences less mechanical stress, extending its lifespan.

Troubleshooting Common Issues

Identifying Leaks

Leaks in magnetic drive micro gear pumps can compromise performance and lead to costly repairs. Operators should inspect seals, connections, and housing for visible signs of fluid leakage. Monitoring operating conditions, such as pressure drops or unexpected fluid loss, helps detect leaks early.

Leak prevention measures, like using high-quality gaskets and ensuring proper assembly, reduce the risk of fluid escaping. Addressing leaks promptly ensures the pump continues to operate efficiently and prevents further damage.

Addressing Noise or Vibration

Unusual noise or vibration often indicates mechanical issues in magnetic drive gear pumps. Misaligned components, worn bearings, or debris in the pump can cause these problems. Operators should inspect the pump for loose parts, damaged bearings, or blockages.

Regular monitoring of vibrations and noise levels helps identify abnormalities before they escalate. Proper installation and alignment minimize mechanical stress, ensuring smooth and quiet operation. Resolving these issues quickly protects the pump from further wear and maintains optimal performance.

Resolving Overheating

Overheating is a common issue that can damage magnetic drive micro gear pumps. It often results from dry runs, excessive friction, or insufficient cooling. Operators should verify fluid levels and ensure the pump is not running without liquid.

Monitoring temperature during operation helps identify overheating early. Installing temperature sensors and ensuring fluid compatibility prevent thermal damage. Addressing overheating promptly extends the lifespan of the pump and maintains its reliability under demanding conditions.

Proactive Tips for Longevity

Using High-Quality Spare Parts

Using high-quality spare parts is essential to maintain magnetic drive micro gear pumps and ensure their long-term reliability. Inferior components often wear out quickly, leading to frequent replacements and reduced pump performance.

Operators should source spare parts from trusted suppliers to match the pump’s specifications. High-quality parts minimize the risk of mechanical failure and help magnetic drive gear pumps operate efficiently under demanding conditions.

Scheduling Preventive Maintenance

Preventive maintenance plays a critical role in extending the lifespan of magnetic drive gear pumps. Operators should establish a regular maintenance schedule that includes cleaning, inspecting, and monitoring the pump’s components.

This proactive approach helps identify potential issues before they escalate into costly repairs. Maintenance logs can track the pump’s condition over time, ensuring that no aspect of its upkeep is overlooked. Consistent preventive maintenance reduces downtime and enhances overall performance.

Training Operators

Properly trained operators are vital for the efficient operation of magnetic drive micro gear pumps. Training programs should cover installation, routine maintenance, and troubleshooting techniques. Skilled operators can quickly identify abnormalities, such as unusual noise or vibration, and take corrective action.

They also ensure that the pump is used within its design limits, preventing damage caused by improper handling. Investing in operator training improves pump performance and reduces the likelihood of operational errors.

Conclusion

Regular maintenance ensures magnetic drive micro gear pumps operate efficiently and last longer. Proactive care reduces downtime, improves performance, and prevents costly repairs. Operators should follow best practices to protect pumps from damage caused by corrosive liquids or flammable liquids. Implementing these strategies maximizes the value of magnetic drive pumps and enhances their reliability.