Finding a reliable micro gear pump manufacturer is not just about price—it’s about long-term performance, safety, and support. Unreliable suppliers often deliver substandard products that fail early or cause compliance issues. In contrast, a trusted manufacturer offers consistent quality, responsive service, and the technical ability to meet specific application needs.

This article walks you through the key factors to evaluate—product quality, certifications, customer support, and industry reputation—so you can make a confident, informed choice that supports long-term efficiency and stability.

Why You Should Pick a Reliable Manufacturer

Problems with Unreliable Manufacturers

Picking the wrong manufacturer can cause big problems. Unreliable companies often make micro gear pumps with poor quality. These pumps might break early, causing delays and costing money. Bad manufacturing can also lead to products that fail safety rules. This could mean fines or safety risks for businesses.

Another issue is bad customer support. Unreliable companies may not help quickly when problems happen. This leaves businesses to fix things on their own. Also, these manufacturers might not have the skills to improve or adjust their products. This makes it hard to grow or work together long-term.

Advantages of Trusted Manufacturers

A trusted manufacturer makes micro gear pumps that work well and last long. Their products need less fixing and save time and money. Reliable companies make pumps that follow safety rules and industry standards. This keeps operations safe and avoids penalties.

Good manufacturers also give great customer support. They solve problems fast and stay in touch with their customers. They have the knowledge to improve and customize products for special needs. Working with a reliable manufacturer means having a partner you can count on. Choosing them helps businesses stay efficient, safe, and successful.

Key Factors to Evaluate Micro Gear Pump Manufacturers

Checking Product Quality and Durability

The quality of a micro gear pump affects how well it works. Good manufacturers make micro gear pumps that last long. They use strong materials like metals that don’t rust. Testing shows if pumps meet flow and pressure needs. Long-lasting micro gear pumps need less fixing. They work well in important things like medical tools.

Looking at Technical Skills and New Ideas

Technical skills help make pumps for special uses. Smart companies make stable pumps with good flow. New ideas help solve new problems. This includes pumps for clean medical tools or steady machines. Look for companies that improve pump designs and flow.

Importance of Certifications and Rules

Certifications show a company follows rules. This means, micro gear pumps are safe for things like medical tools. ISO certifications mean they focus on quality. Check if the company meets safety and green rules. This means safe and reliable pumps.

Customer Help and After-Sales Service

Good customer help shows a company cares. Reliable companies fix problems fast. They offer spare parts and advice. Check how fast they help and solve issues. This keeps micro gear pumps working and builds trust.

Checking Reputation and Reviews

A company’s reputation shows how reliable they are. Good reviews mean happy customers. Online reviews and stories show how micro gear pumps work in real life. Choose companies known for making good small pumps. A strong reputation means stable and reliable pumps.

Guidelines for Choosing a Micro Gear Pump Manufacturer

Matching Micro Gear Pumps to Your Application Needs

Picking the right pump depends on how you’ll use it. Each use has special needs like flow, pressure, and materials. For example, medical tests need micro gear pumps that move exact amounts. These pumps must avoid mixing fluids to stay safe. Water treatment needs pumps that handle different liquids well. They must also work steadily and efficiently.

Good manufacturers make pumps for these specific jobs. They give clear details to match your needs. They also solve problems like mixing fluids or wrong materials. This keeps the pump working safely and properly. Choose makers who know your industry and can adjust to your goals.

Practical Steps: Facility Visits, Samples, and Quotes

Checking a manufacturer’s reliability takes hands-on effort. Visiting their factory shows how they make and test micro gear pumps. You can see if they follow rules and make strong products. Watching their process helps you trust their quality and care.

Ask for pump samples to test in real situations. This shows if they meet your needs, like avoiding fluid mixing. For water treatment, pumps must work well with changing liquids. Testing samples shows how steady and strong they are over time.

Finally, get detailed price quotes to compare options. Good companies share clear costs, warranties, and support plans. This helps you pick a partner who offers value and quality.

Conclusion

Choosing a trustworthy manufacturer helps micro gear pumps last longer and work better. Companies should carefully check products and reviews before deciding. A good manufacturer makes quality pumps and helps businesses grow. Spend time picking the right one for long-term success.

Looking for a Reliable Micro Gear Pump Manufacturer?

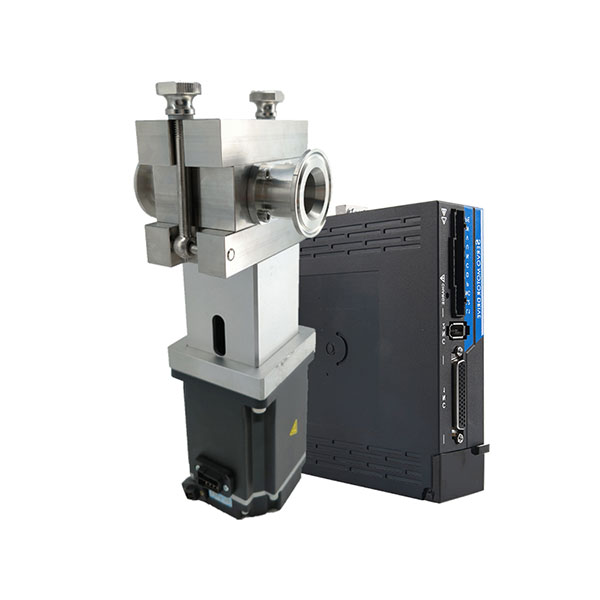

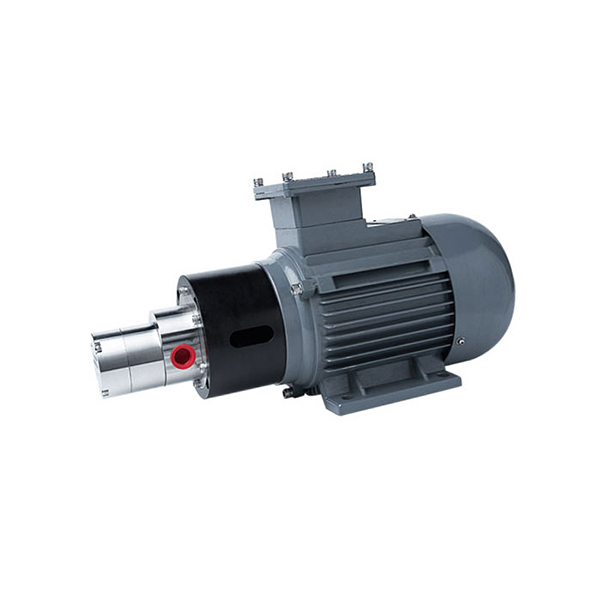

CHENHUI specializes in manufacturing high quality micro gear pumps designed for accurate metering. Our pumps deliver stable low-flow performance with high repeatability, making them ideal for dosing systems, fluid sampling, chemical injection, and other applications where flow precision is critical.

With customizable configurations, we support OEM clients with fast sampling, flexible MOQ, and direct technical assistance. If your project requires consistent micro-dosing with long service life, CHENHUI is your reliable manufacturing partner. Contact us today to discuss your specific application.