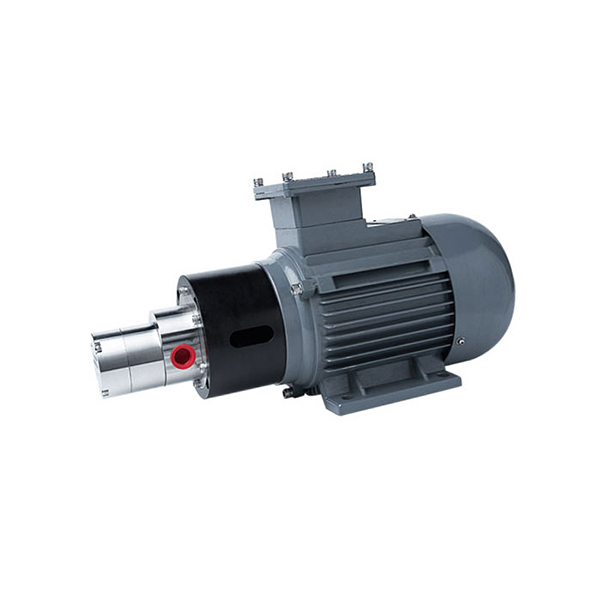

Gear pump rotation direction determines how fluid moves through the system. Incorrect rotation can disrupt flow, reduce efficiency, and damage components. Identifying the correct rotation ensures smooth operation and prevents costly failures. This guide explains how to identify rotation direction, whether it can be reversed, and steps to change it safely.

How to Determine Gear Pump Rotation Direction

Identifying rotation arrows or markings

Gear pump manufacturers often include rotation arrows or markings on the pump housing. These indicators show the intended rotation direction, whether clockwise or counterclockwise.

Look for these markings near the shaft or on the pump body. They provide a quick and reliable way to confirm the correct rotation. If the markings are unclear or missing, consult the manufacturer’s manual for clarification.

Determining suction and discharge ports

The suction port and discharge port locations also help identify the rotation direction. In most gear pumps, the suction port is larger and positioned on the side where fluid enters the pump.

The discharge port, typically smaller, is located where fluid exits under pressure. For a pump with clockwise rotation, the suction port is usually on the left side when viewed from the drive end. Observing these ports ensures proper installation and operation.

Recognizing the role of the pressure relief valve

The pressure relief valve plays a critical role in protecting the gear pump from overpressure. Its position can also indicate the rotation direction. For a pump with clockwise rotation, the valve is often aligned with the discharge port.

This alignment ensures excess pressure is relieved efficiently. Always verify the valve’s placement to confirm the pump’s rotation and prevent potential damage.

Steps for Safe and Effective Gear Pump Rotation Changes

Reviewing the manufacturer’s manual

Before attempting to change the rotation of a gear pump, reviewing the manufacturer’s manual is essential. The manual provides specific instructions tailored to the pump model. It outlines whether the pump supports reversible operation and details the steps required to change direction.

Skipping this step can lead to improper adjustments or damage to internal components. Users should also confirm the compatibility of the hydro gear pump with the intended system setup. This ensures the suction and discharge ports, as well as the drive shaft gear, align correctly after the modification.

Adjusting internal components

Changing the rotation direction often involves adjusting internal components. Start by disassembling the pump carefully to access the internal mechanisms. Rotate the drive shaft gear to align it with the new direction of flow.

Some models may require repositioning the pressure relief valve or modifying the lubrication path to support the new rotation. Ensure all parts are reassembled securely to prevent leaks or operational issues.

Using the correct tools and following the manual’s guidance minimizes the risk of errors during this process.

Testing for correct rotation after reassembly

After reassembly, testing the pump is crucial to verify the new rotation direction. Connect the pump to the system and observe the flow of fluid. For a clockwise rotation, ensure the suction port draws fluid in while the discharge port expels it under pressure.

Monitor the pump for unusual noises, leaks, or overheating, which may indicate improper adjustments. Testing ensures the pump operates efficiently and prevents potential damage caused by incorrect rotation.

Key Considerations for Changing Rotation Direction

Ensuring lubrication path compatibility

The lubrication path inside a gear pump plays a vital role in maintaining smooth operation. When changing the rotation direction, the lubrication path must align with the new flow direction.

A misaligned path can lead to insufficient lubrication, causing wear on the drive shaft gear and other internal components.

Users should inspect the pump’s internal design to ensure the lubrication channels support the intended rotation. For hydro gear pumps, this step is especially critical due to their reliance on precise lubrication for high-pressure performance.

Following the manufacturer’s guidelines helps avoid operational issues.

Aligning suction and discharge ports

The suction port and discharge port must align correctly after altering the rotation direction. The suction port should always draw fluid into the pump, while the discharge port expels it under pressure. Reversing the rotation without adjusting these ports can disrupt fluid flow, reducing efficiency and potentially damaging the pump.

Users should verify the port alignment during reassembly. Observing the fluid flow during testing ensures the ports function as intended. Proper alignment prevents operational failures and maintains system efficiency.

Verifying pressure relief valve functionality

The pressure relief valve protects the pump from damage caused by high pressure. Its position must correspond to the discharge port after the rotation change. If the valve remains misaligned, it may fail to relieve excess pressure, leading to potential system failure.

Users should reposition the valve as needed and test its functionality during operation. Ensuring the valve operates correctly safeguards the pump and extends its lifespan. Regular maintenance checks further enhance reliability.

Conclusion

Understanding gear pump rotation direction ensures efficient operation and prevents damage. Following manufacturer guidelines is essential for maintaining system compatibility.

For complex tasks, consulting professionals is highly recommended. Pumps designed for bidirectional rotation or bi-directional pumping require careful adjustments to function correctly, ensuring optimal performance and longevity.

FAQs

1. Does a gear pump have a specific direction of rotation?

Yes, a gear pump usually has a specific direction of rotation. It is designed to turn either clockwise or counterclockwise, depending on how it is built. The direction controls the flow of the fluid.

If the pump runs in the wrong direction, it may not pump at all or could damage the internal parts. Always check the arrow on the pump body or the manufacturer’s manual before use.

2. What is the direction of rotation of a pump?

The direction of rotation of a pump refers to the way the shaft or motor turns. It can be clockwise (CW) or counterclockwise (CCW). The correct direction is important because it controls how fluid moves through the pump.

Most manufacturers mark the rotation direction with an arrow on the pump housing. Running the pump in the wrong direction can cause poor performance or damage.

3. What happens if a gear pump runs backwards?

If a gear pump runs backwards, it can cause several problems. The fluid may flow in the wrong direction or not flow at all. In some cases, running backward can damage the seals or gears inside the pump.

It can also cause leaks or lower pressure. Always follow the correct rotation direction shown on the pump label to avoid damage and ensure safe operation.

4. Can a gear pump work in both directions?

Some gear pumps are designed to work in both directions, but most are not. Standard gear pumps usually have one fixed direction. If used in reverse, they may not work properly and could suffer damage.

However, special bidirectional gear pumps are available for systems that need flow in two directions. Always check the pump specifications before trying to run it both ways.

5. Can You Reverse the Rotation of a Gear Pump?

Gear pumps come in two main types: reversible and non-reversible.

- Reversible models allow the rotation direction to be changed, enabling both clockwise and anti-clockwise operation. These pumps are designed with internal components that can handle fluid flow in either direction.

- Non-reversible models, however, operate in only one direction. Their internal design, including the drive shaft gear and lubrication paths, supports a single rotation direction.

Identifying the type of gear pump is essential before attempting any modifications. The manufacturer’s manual often provides this information.