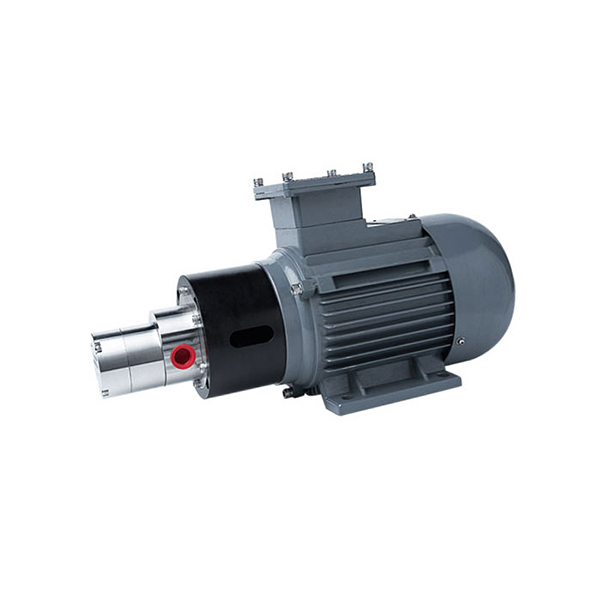

Choosing the right materials in micro gear pump design isn’t just a technical decision—it directly affects performance, lifespan, and how the pump handles different fluids. Whether you’re designing lab dosing systems, compact analyzers, or industrial microfluidic devices, material selection can make or break your results.

In this guide, we break down the most important materials used in CHENHUI’s custom micro gear pumps, helping you make the best choice for your specific application.

Why Material Selection Matters in Micro Gear Pumps?

In micro gear pump systems, even the smallest component plays a critical role. From precise fluid dosing in laboratories to rugged operation in compact industrial setups, the materials used in each part of the pump determine how well it withstands stress, resists corrosion, and maintains performance over time.

The right gear pump materials ensure not just efficient operation, but also longevity, accuracy, and safety in demanding environments. That’s why understanding material compatibility is essential before any system design begins.

Main Materials of Micro Gear Pumps

1. Gears

In micro gear pumps, selecting the right gear material is critical due to strict requirements on dosing accuracy and chemical compatibility. High-performance thermoplastics are commonly used for this purpose, and CHENHUI chooses PEEK (Polyetheretherketone) as the standard material for pump gears.

PEEK offers a combination of high strength, chemical resistance, and thermal stability up to 250°C, making it highly reliable in continuous operations involving aggressive fluids. It maintains dimensional stability under pressure and does not deform during prolonged use.

Due to its balanced rigidity and toughness, PEEK ensures long-term accuracy in dosing, which is essential for medical equipment, laboratory analysis, and compact chemical systems.

2. Pump Body

316 stainless steel is a widely accepted material for the body of micro gear pumps due to its corrosion resistance and mechanical strength. CHENHUI uses 316 stainless steel for its pump bodies because it offers excellent resistance to chlorides, acids, and other harsh chemicals.

Its non-reactive nature makes it suitable for precision systems where material stability is essential. This material is commonly used in compact industrial setups, laboratory dosing systems, and medical devices where cleanliness, chemical resistance, and long-term reliability are critical.

3. Shafts

In micro gear pumps, the shaft is a critical mechanical component. It is responsible for transmitting torque and maintaining alignment under rotational stress. CHENHUI selects only high-performance shaft materials that offer long-term durability, chemical compatibility, and structural integrity, even in highly demanding environments.

These shaft materials are chosen specifically to match the needs of microfluidic, dosing, medical, and lab-scale industrial systems, where even the smallest deformation or contamination could compromise system performance.

-

Ceramic (Alumina or Zirconia)

Ceramic shafts are used in CHENHUI pumps for ultra-high precision and metal-free environments. Materials like Alumina (Al₂O₃) or Zirconia (ZrO₂) are extremely hard, chemically inert, and dimensionally stable. These shafts are the go-to choice when:

- The pumped fluid is highly reactive with metals.

- The application requires absolute purity (e.g., in analytical instruments or medical diagnostics).

- The environment involves high temperatures or abrasive fluids.

Their wear resistance and corrosion immunity ensure stable, vibration-free operation with minimal maintenance.

-

Tungsten Steel

It is used in CHENHUI pumps for their extreme mechanical strength, wear resistance, and low thermal expansion. Tungsten steel shafts are best suited for:

- High-load or high-pressure microfluidic systems.

- Applications involving abrasive or high-viscosity fluids.

- Long-running equipment requires an extended operational life.

Tungsten steel maintains its shape under stress and resists deformation better than most metals. It’s often selected for mission-critical systems where component failure is not an option.

-

Titanium Alloy

For applications where chemical aggressiveness, low weight, and bio-compatibility intersect, CHENHUI uses titanium alloy shafts. These offer:

- Outstanding corrosion resistance, even against halides, chlorides, and oxidizers.

- High strength-to-weight ratio, which improves efficiency in mobile or battery-powered systems.

- Compatibility with high-purity and biomedical fluids.

Titanium is especially valued in semiconductor processes, biopharma dosing, and high-end medical equipment, where even trace contamination must be avoided.

Selecting the right shaft material helps ensure:

- Reduced wear and maintenance needs.

- Improved chemical resistance and cleanliness.

- Stable performance in high-precision dosing.

- Longer operational life in continuous-use environments.

By offering a range of shaft materials, CHENHUI allows engineers and designers to tailor the pump to very specific fluid types, temperatures, and system conditions.

Factors to Consider When Selecting the Materials

While selecting materials for micro gear pumps, keep in mind the following considerations:

- Chemical Compatibility: Materials must endure the specified chemicals and fluids for the particular application.

- Thermal Stability: Materials must retain their properties within normal operating ranges for the application, with regard to temperature.

- Mechanical Strength: Each component must be able to withstand the mechanical stresses during the operation of the pump.

- Wear Resistance: Materials must be capable of resisting wear to ensure the long-term operational life of the pump while maintaining performance.

Conclusion

Material choice in micro gear pump design isn’t a background detail—it’s a defining factor that impacts every aspect of performance. By selecting materials tailored to your application’s chemical, thermal, and mechanical demands, you ensure the pump runs longer, safer, and more efficiently.

Whether you’re engineering for medical precision, chemical resistance, or miniaturization, understanding your material options puts you a step ahead in building smarter, more reliable microfluidic systems.

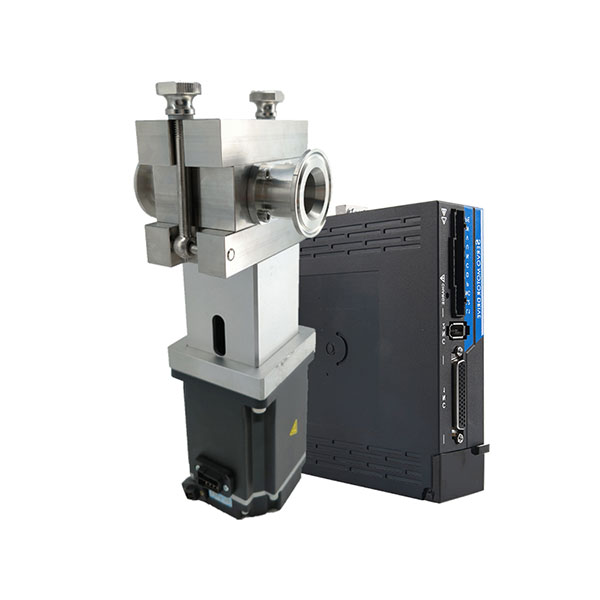

Ready to Customize a Micro Gear Pump That Meets Your Exact Needs?

CHENHUI offers precision-engineered micro gear pumps designed with material combinations tailored for your chemical, thermal, and mechanical requirements. Contact us today to discuss your application, request a sample, or start a custom order. Let’s build the right solution for your microfluidic system.