Introduction

In the world of fluid transferring, magnetic gear pumps stand out as a reliable, efficient, and versatile solution for handling a wide range of liquids. Whether you’re in the pharmaceutical, chemical, food processing, or automotive industry, understanding how these pumps work and their benefits can help you make informed decisions about your fluid transfer needs.

What is a Magnetic Gear Pump?

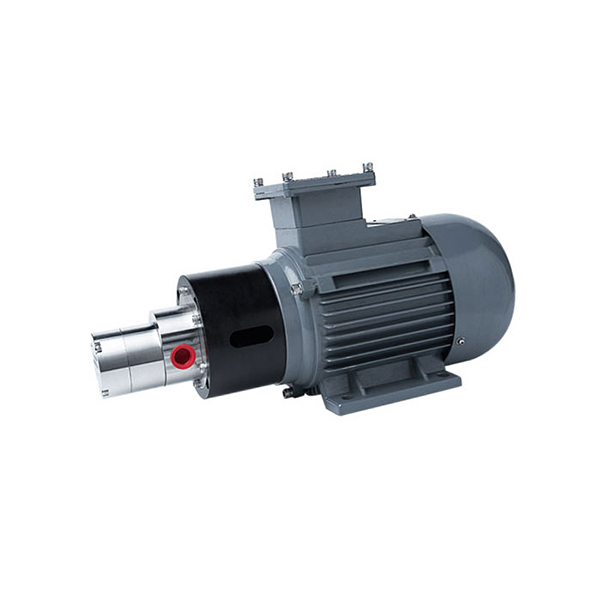

Magnetic gear pump is a type of positive displacement pump that uses magnetic forces to drive the rotation of gears, which in turn moves the fluid. Unlike traditional gear pumps that rely on a mechanical seal to transmit torque to the gears, magnetic gear pumps use a magnetic coupling system, which eliminates the need for direct contact between the motor and the fluid. This seal-less magnetic drive mechanism allows magnetic gear pumps to safely handle corrosive fluids and volatile chemicals without the risk of leakage.

Magnetic Gear Pump Working Principle

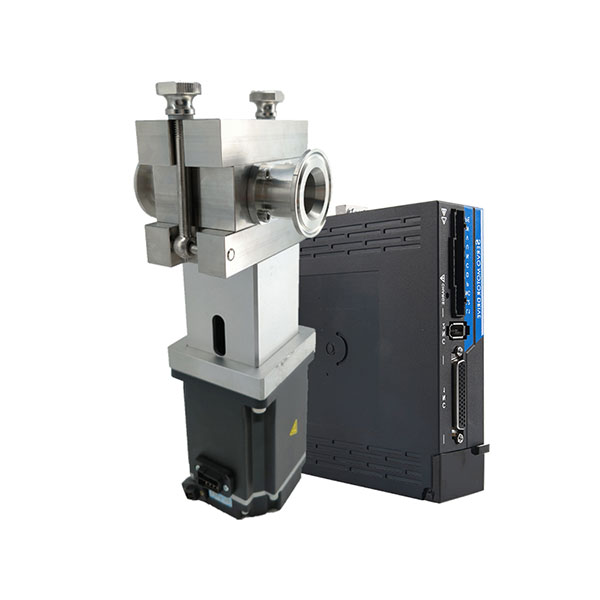

The pump operates through a magnetic coupling system, which consists of two main parts: the drive side, connected to the motor, and the driven side, located within the pump housing. The motor generates rotational force through the external magnetic field, which is then transferred to the internal magnetic assembly without physical contact.

This magnetic force drives the internal gears within the pump, effectively moving the fluid through the pump. The design eliminates the friction and wear associated with traditional mechanical transmission, enhancing both efficiency and reliability.

Why are magnetic drive pumps used?

- Seal-less Design: One of the most significant advantages of magnetic gear pumps is their seal-less design. Traditional pumps use mechanical seals, which can wear out over time and lead to leaks. Since magnetic gear pumps adopt static sealing, the risk of leaks is greatly reduced. This makes them an ideal choice for handling hazardous or corrosive liquids.

- Leak-Free Operation: The absence of seals also ensures that the pump operates without any leakage, which is critical in industries where maintaining the purity of the fluid is essential. For instance, in the pharmaceutical or food processing industries, even a small amount of contamination can have serious consequences.

- High Efficiency and Reliability: Magnetic gear pumps are known for their high efficiency and reliability. The magnetic coupling eliminates the need for complex mechanical seals, which reduces maintenance requirements and extends the pump’s lifespan. Additionally, the design of the pump allows for smooth and efficient operation even with viscous fluids.

- Versatility: Micro magnetic gear pumps are favored for precise metering of aggressive fluids like acids, solvents, or oils. They are commonly used in industries where precise fluid control is required, such as in chemical dosing systems, fuel transfer, and hydraulic applications.

- Compact and Quiet: Magnetic gear pumps are typically compact and operate quietly, making them suitable for applications where space is limited and noise levels need to be minimized. Their compact size also makes them easy to integrate into existing systems without requiring significant modifications.

Applications of Magnetic Gear Pumps

Magnetic gear pumps are used in a variety of industries and applications.

- In the chemical industry, they are employed for the safe transfer of corrosive acids, bases, and solvents.

- The pharmaceutical industry relies on these pumps for precise dosing of active ingredients and other liquids.

- In food processing, they ensure the hygienic transfer of oils, syrups, and other food-grade liquids without contamination.

- In automotive applications, magnetic gear pumps are used for fuel transfer, lubrication, and cooling systems.

- Magnetic drive gear pumps are also frequently adopted in laboratory and analytical instruments, where a micro magnetic gear pump is essential for accurate fluid handling in low volumes.

Magnetic drive gear pumps are widely used for transferring aggressive chemicals like sulfuric acid, nitric acid, and organic solvents. Their sealless, corrosion-resistant design ensures safe and reliable fluid transfer in environments where traditional pumps may fail.

Magnetic Gear Pump vs. Canned Motor Pump

Magnetic drive and canned motor pumps are two types of sealless pumps, each with unique operating mechanisms. In magnetic drive pumps, permanent magnets generate magnetic forces that turn the impeller, eliminating the need for mechanical seals. In contrast, canned motor pumps use a rotor and stator system powered by alternating current to create a magnetic field that drives the impeller.

Magnetic drive pumps offer more flexibility in adjusting operating points through motor specifications. However, canned motor pumps tend to be more compact, as their rotor and impeller are integrated into a single design.

When it comes to fluid containment, magnetic drive pumps typically feature a single containment zone, while canned motor pumps have double containment with a sealed stator liner, providing added safety in case of a rupture.

Magnetic Drive Gear pump vs. Mechanical Seal Pump

Magnetic drive gear pumps are becoming increasingly popular over traditional mechanical seal pumps, especially in industries where fluid leakage control and handling of aggressive chemicals are critical. Unlike mechanical seal pumps, which rely on dynamic seals that require constant monitoring and maintenance, magnetic drive pumps offer a much safer and more reliable solution.

Magnetic drive pumps provide zero leakage, reducing the risk of spills and contamination. They also minimize the need for constant maintenance and monitoring, which leads to significant cost savings. Additionally, magnetic drive pumps put less strain on bearings and shafts, resulting in higher operational efficiency and fewer vibrations during start-up and shut-down.

On the other hand, mechanical seal pumps come with higher maintenance costs, require frequent monitoring of barrier fluid levels, and can be prone to mechanical failures due to increased stress on components. As a result, magnetic drive pumps are the more cost-effective and safer option for handling chemicals and other challenging fluids.

FAQs

1: Are magnetic gear pumps suitable for corrosive fluids?

Yes, their seal-less design makes them ideal for acids, solvents, and aggressive chemicals.

2: Can magnetic gear pumps handle micro-dosing?

Absolutely. Micro magnetic gear pumps are commonly used in pharmaceutical and laboratory equipment where precision is key.

3: What industries benefit most from magnetic gear pumps?

Chemical processing, pharmaceuticals, food and beverage, automotive, and lab instrumentation all rely on magnetic gear pump technology for safe and accurate fluid transfer.

Conclusion

Magnetic gear pumps offer a powerful combination of efficiency, reliability, and safety, making them an ideal choice for a wide range of fluid transfer applications. Their seal-less design, leak-free operation, and versatility make them particularly valuable in industries where maintaining the purity and integrity of the fluid is paramount.

Whether you are handling hazardous chemicals or need precise control over fluid flow, magnetic gear pumps provide a dependable solution that you can trust. Understanding how magnetic gear pumps work—especially their seal-less design and precision—can help engineers, buyers, and plant managers select safer, more efficient solutions for chemical dosing, fuel transfer, and beyond.

Partner with CHENHUI for High Quality Magnetic Gear Pumps

As a trusted magnetic gear pump manufacturer, CHENHUI provides OEM options for micro and industrial-grade pumps used in high-pressure and chemical handling applications. Our micro gear pumps feature magnetically coupled designs for zero leakage and low-maintenance operation. Ideal for high-pressure, low-flow applications, it handles aggressive fluids safely and efficiently. Its compact size and precision make it perfect for industries like chemicals, pharmaceuticals, food processing and automotive, ensuring reliable, long-lasting performance.

BUY MICRO MAGNETIC GEAR PUMPS HERE