Micro gear pumps are compact, precision devices designed to move fluids in controlled volumes. Flow rate plays a critical role in determining how efficiently these pumps transfer liquids. Industries rely on these pumps in applications like chemical dosing, medical devices, and fuel delivery, where consistent flow and stable pressure are essential.

What is Flow Rate in Micro Gear Pumps?

Flow rate refers to the volume of fluid a pump moves within a specific time frame. It is typically measured in units such as liters per minute (L/min) or milliliters per second (mL/s).

This parameter indicates how efficiently a micro gear pump transfers liquid through a system. A consistent flow rate ensures that processes relying on precise fluid delivery, such as chemical dosing or medical applications, operate smoothly.

What is Pressure in Micro Gear Pumps?

Pressure refers to the force exerted by a fluid per unit area within a system. It is commonly measured in units such as bar or pounds per square inch (psi). In micro gear pumps, pressure indicates the pump’s ability to overcome resistance and move fluid through the system.

This parameter is critical for ensuring that the pump delivers fluids effectively, especially in applications requiring precise control.

Relationship Between Flow Rate and Pressure

How increasing pressure affects flow rate

In micro gear pumps, pressure and flow rate share an inverse relationship. As pressure increases, the pump must work harder to overcome system resistance. This added effort often reduces the flow rate because the pump’s capacity to move fluid is limited by its design and operating conditions.

For example, when a system requires higher pressure to push fluid through narrow tubing, the pump may deliver a lower flow rate to maintain stability.

Why flow rate drops as pressure rises

Internal leakage, also known as slip, is a key reason why flow rate decreases as pressure rises. Slip occurs when fluid bypasses the gears due to high pressure, reducing the volume of liquid delivered to the system.

This phenomenon is more pronounced in pumps handling low-viscosity fluids or operating at their maximum pressure limits. Minimizing slip requires selecting a pump with tight tolerances and ensuring compatibility with the fluid’s properties.

Practical limits and efficiency considerations

Every micro gear pump has practical limits for flow rate and pressure. Exceeding these limits can lead to inefficiencies, such as increased energy consumption or wear on internal components.

Users should operate pumps within their specified ranges to maintain efficiency and prolong service life. Regular monitoring of system conditions, including pressure and flow rate, helps identify potential issues before they impact performance.

Key Factors Influencing Flow Rate and Pressure

Fluid Properties and Their Impact

Fluid properties significantly influence the performance of a gear pump. Viscosity, which measures a fluid’s resistance to flow, directly affects the pump’s ability to maintain consistent flow rate.

High-viscosity fluids require more energy to move, potentially reducing efficiency. Density also plays a role, as denser fluids exert greater pressure on the pump’s components.

Temperature changes can alter these properties, impacting both flow rate and pressure. Selecting a pump compatible with the fluid’s characteristics ensures optimal operation.

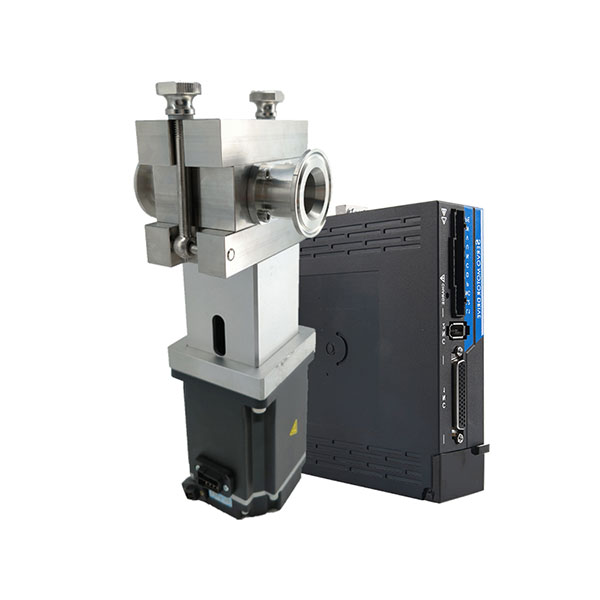

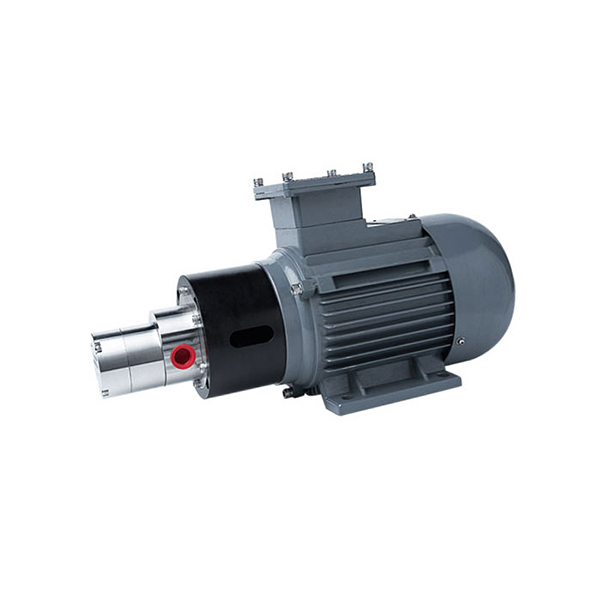

Role of Pump Design and Size

The design and size of a gear pump determine its capacity to handle specific flow and pressure requirements. Larger pumps typically deliver higher flow rates, while smaller pumps excel in precision applications.

Gear design, including the number of teeth and their alignment, affects fluid movement and minimizes internal leakage.

Material selection for gears and housing impacts durability and resistance to wear. Pumps with advanced designs often achieve better efficiency and reliability, making them suitable for demanding applications.

External System Conditions and Backpressure

External system conditions, such as tubing diameter and system layout, create backpressure that influences pump performance. Narrow tubing or long pipelines increase resistance, requiring the pump to generate higher pressure to maintain flow.

System cleanliness also matters; debris or blockages can disrupt fluid movement and strain the pump. Regular maintenance of external components reduces backpressure and ensures smooth operation.

Proper system design, including minimizing unnecessary restrictions, enhances pump efficiency and prolongs its lifespan.

Practical Strategies to Optimize Micro Gear Pump Performance

Calibrating for Accurate Flow Rate

Calibrating a micro gear pump ensures precise fluid delivery. Users should measure the actual flow rate under operating conditions and compare it to the desired value.

Adjustments can be made by fine-tuning the pump’s speed or modifying system parameters. Regular calibration minimizes errors caused by wear, fluid property changes, or environmental factors. For critical applications, using flow meters to monitor performance in real time enhances accuracy.

Choosing the Right Gear Pump for Your Needs

Selecting the appropriate gear pump depends on the application’s specific requirements. Users should evaluate factors such as flow rate, pressure, and fluid compatibility.

Pumps designed for high-viscosity fluids may not perform well with low-viscosity liquids, and vice versa. Material selection also matters; for example, corrosive fluids require pumps with chemically resistant components.

Consulting performance curves and manufacturer specifications helps identify the best match for the system.

Maintaining Fluid Viscosity and Temperature

Fluid viscosity and temperature directly impact a pump’s efficiency. High-viscosity fluids can strain the pump, reducing flow rate and increasing energy consumption.

Conversely, low-viscosity fluids may lead to internal leakage. Maintaining the fluid within the recommended temperature range ensures consistent viscosity and optimal performance.

Installing heaters or coolers in the system can help regulate temperature, especially in environments with fluctuating conditions.

Implementing Regular Maintenance Practices

Routine maintenance extends the lifespan of a gear pump and ensures reliable operation. Users should inspect components such as gears, seals, and bearings for wear or damage.

Cleaning the pump and system prevents blockages caused by debris or residue. Lubricating moving parts reduces friction and minimizes wear. Establishing a maintenance schedule based on the pump’s operating conditions helps prevent unexpected failures and costly downtime

Conclusion

Optimizing flow rate and pressure in micro gear pumps requires a clear understanding of how fluid properties, pump design, and system conditions interact. Staying within specified performance limits ensures efficiency, reduces wear, and extends service life.

By selecting the right pump, maintaining fluid consistency, and performing regular maintenance, users can achieve precise and stable fluid delivery. For applications where accuracy and reliability matter, fine-tuning these parameters is necessary.