When accuracy is required to move small volumes of liquid, the decision usually comes between a gear pump vs piston pump. Both operate differently and are better suited for different applications. But if you’re designing a project that requires constant, low flow rates – such as in medical dosing, chemical processing, or lubrication systems, selecting the right one can be more important than you think.

In this article, we will describe the fundamentals of each type, compare their performance, and assist you in determining which is the more suitable choice for low-flow applications.

What Is a Gear Pump?

A gear pump is a type of positive displacement pump that uses two meshing gears to move fluid. As the gears rotate, they trap fluid between the gear teeth and the pump casing, carrying it from the inlet to the outlet in a consistent flow. Gear pumps are known for their simple structure, steady output, and ability to handle a wide range of viscosities.

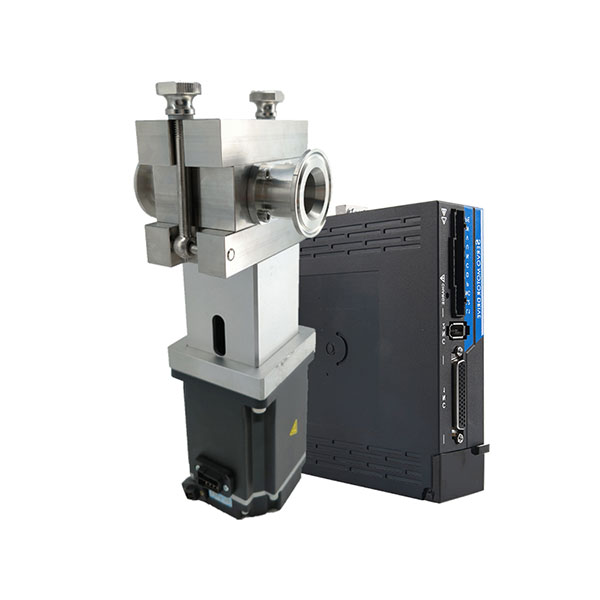

Within this category, micro gear pumps are a more compact variant designed for low flow and precision-demanding applications. They maintain the same working principle but operate at a much smaller scale. Many models also feature magnetic coupling, which eliminates shaft seals to prevent leakage and reduce maintenance.

Micro gear pumps are especially used for:

- Medical and laboratory use

- Fuel transfer

- Chemical dosing

- Cooling and lubrication systems

It is not only compact and quiet but also offers accurate delivery and strong suction – even with low-viscosity liquids.

What Is a Pistons Pump?

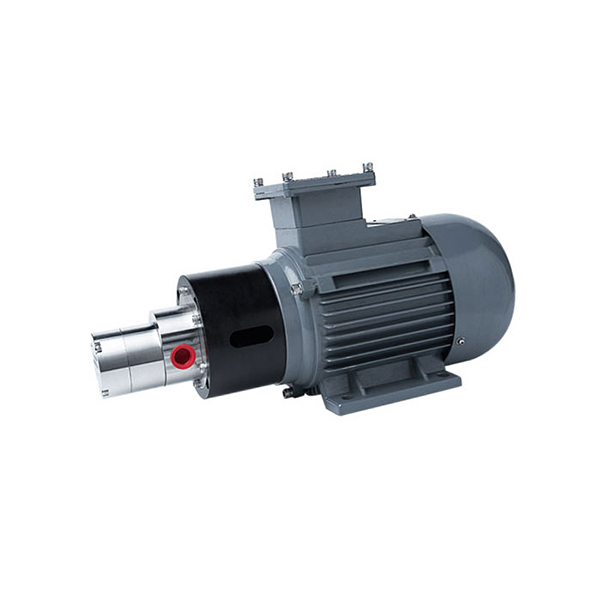

Piston Pumps operates on a piston that moves back and forth within a cylinder. This action draws fluid in on one stroke and replaces it on the other. Due to this configuration, they have the ability to produce extremely high pressure and are ideal for heavy-duty applications. You’ll often find this in:

- Construction machinery

- Industrial hydraulic systems

- Equipment that requires high-pressure fluid delivery

They’re strong and can support a wide range of forces and flow rates. They’re usually larger, louder & require more maintenance because of their moving parts.

Which Pump Handles Low Flow Better?

For low-flow use, precision is critical. Micro gear pump provide smooth-flowing fluid without pulsation, which means you’re getting the same flow each & every time. This is important in industries like pharmaceuticals or food production, where even a minimal variation can lead to a vast difference.

Other hand piston pumps are strong and tend to produce flow in pulses because of their back-and-forth action. This can result in less predictable delivery on low-flow applications. Plus, they’re more than what’s needed for tasks that don’t require high pressure. Therefore, if your application requires precise dosing, stable flow, or compact systems, micro gear pumps are designed for that.

Why Choose Micro Gear Pump: Efficiency and Durability

One of the biggest reasons to choose a micro gear pump is its long-term reliability. Due to its sealed design with magnetic coupling, there’s little to no risk of leaks. There’s also less wear on the parts, so you don’t need to service it often.

Longevity also comes from smart material choices. We use stainless steel housing and PEEK gears, a high-performance plastic known for its strength & chemical resistance. This makes our product tough enough for harsh fluids and demanding environments.

On the other hand, the piston pump can go down faster because of the many moving parts involved. Their seals may leak over time, especially when exposed to aggressive chemicals or extreme temperatures.

Comparison Table to Understand Better

Comparing both is helpful in examining a few key characteristics. Following is a breakdown of how they compare:

| Feature | Micro Gear Pump | Piston Pump |

| Flow Rate | Low, steady, and precise | Higher flow rates possible |

| Pressure | Moderate, up to high for size | Can handle very high pressure |

| Maintenance | Low maintenance | Requires regular maintenance |

| Size | Compact, fits in tight spaces | Larger, bulkier equipment |

| Noise | Quiet operation | Can be noisy |

| Cost | More affordable | Typically more expensive |

| Leakage | Leak-free with magnetic coupling | May leak due to mechanical seals |

| Best for | Precise dosing, small-scale applications | Heavy-duty, high-pressure tasks |

As you can see, each has its strengths. However, when size, quiet operation, and precision are necessary for the task, gear pumps are clearly the better choice. If we examine the gear pump vs piston pump closely, micro gear pumps obviously provide a better combination of precision, simplicity, and cost-effectiveness – particularly when high pressure is not needed.

When Should You Choose a Micro Gear Pump?

- Low flow and precise dosing

- Handling chemicals, lubricants, or coolants

- Systems where leaks are unacceptable

- Compact machines or equipment

- Low noise and low energy usage

Micro gear pumps are also perfect for metering applications in the pharmaceutical and food industries, as well as in fuel cells and lab equipment. So, when evaluating the gear pump vs piston pump, the gear pump is clearly better suited for sensitive and compact setups.

Conclusion

If you’re working on a project that involves low flow, especially with delicate fluids or in confined spaces, micro gear pump is your best choice. These are efficient, accurate and cost-effective. They require minimal maintenance and provide leak-free operation, making them a smart investment for many industries.

In contrast to pistons, which are designed for power & not for precision, micro gear pumps achieve the ideal combination of size, performance, and reliability.

Partner With CHENHUI for Reliable Low Flow Fluid Transfer Solutions

At CHENHUI, we specialize in high-quality magnetic drive micro gear pumps that are built for the toughest environments. Whether you need a custom solution for chemical dosing, lubrication, fuel transfer, or any other precise application, we’ve got you covered.

Our products are engineered to deliver smooth performance with minimal maintenance & our team is here to support you every step of the way. Contact us today to learn more about our magnetic gear pump solutions or request a free consultation or sample quote tailored to your project needs.