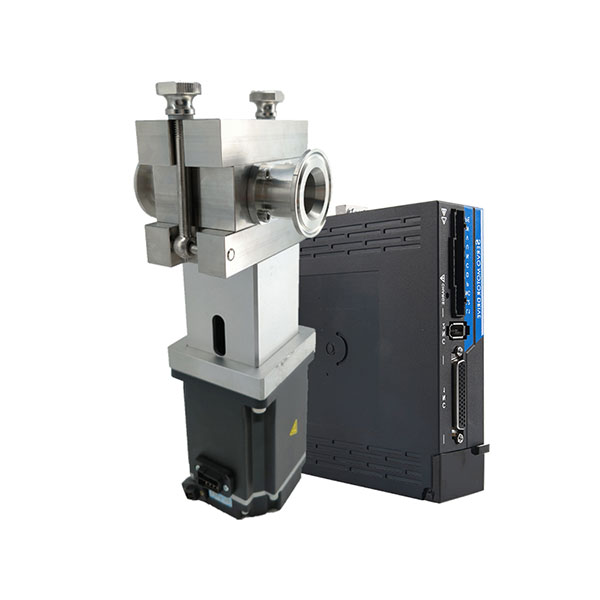

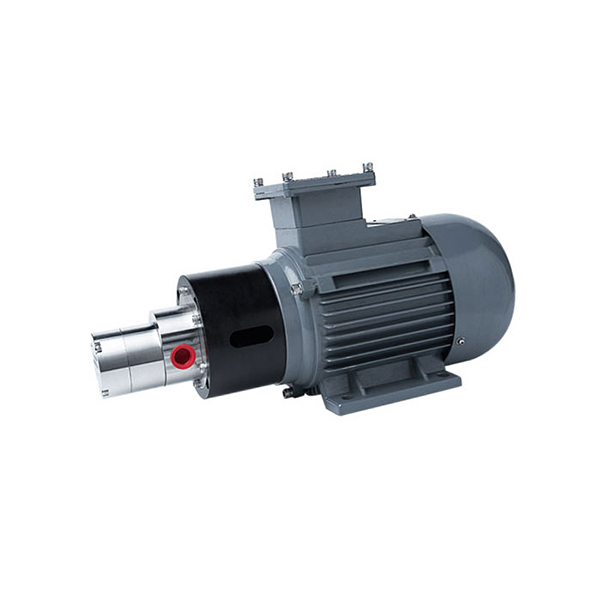

A micro gear pump moves fluids with precision in industrial and medical applications. The shaft transmits rotational energy, making its material crucial for performance. Selecting the right material ensures reliability and durability. Poor choices can lead to wear or failure, especially when handling corrosive or high-temperature fluids.

What is a Pump Shaft?

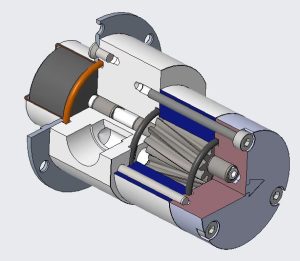

Purpose of the shaft in a micro gear pump

The shaft in a micro gear pump plays a critical role in its operation. It serves as the central component that transfers rotational energy from the motor to the gears. This energy drives the movement of the gears, which, in turn, displaces fluid through the pump. Without the shaft, the pump cannot function effectively.

In addition to energy transfer, the shaft ensures the alignment of the gears. Proper alignment minimizes wear and tear, extending the lifespan of the pump. The shaft also helps maintain consistent fluid flow, which is essential for applications requiring precision.

How the shaft affects the overall pump performance

The material of the shaft significantly influence the performance of a micro gear pump. A well-designed shaft reduces friction and ensures smooth operation. Materials with high strength and durability can withstand the mechanical stresses of continuous use.

Shafts exposed to corrosive fluids or harsh environments must resist degradation to maintain efficiency. Temperature resistance also matters, especially in pumps handling high-temperature fluids. A poorly chosen shaft material can lead to misalignment, increased wear, and eventual pump failure.

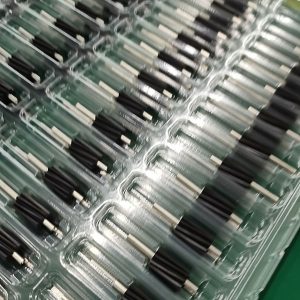

Materials Commonly Used in Micro Gear Pump Shafts

Stainless Steel

Stainless steel is one of the most popular materials for micro gear pump shafts. Its high strength and excellent corrosion resistance make it suitable for handling a wide range of fluids, including those with acidic or alkaline properties. This material also performs well in high-temperature environments, maintaining its structural integrity under stress.

Another advantage of stainless steel is its durability. It resists wear and tear, even in continuous operation. This makes it a reliable choice for industrial applications where pumps operate for extended periods. Additionally, its smooth surface reduces friction, which helps improve the efficiency of the pump.

Ceramic

Ceramic materials are ideal for micro gear pump shafts in highly specialized applications. They offer exceptional hardness and wear resistance, making them suitable for handling abrasive fluids. Ceramics also exhibit excellent chemical resistance, which allows them to perform well in environments with aggressive chemicals.

One of the key benefits of ceramic shafts is their ability to withstand extreme temperatures. They maintain their properties even in high-heat conditions, making them a preferred choice for pumps used in industries like chemical processing. However, ceramics are brittle and may not be suitable for applications involving high mechanical stress.

PEEK

Polyether ether ketone (PEEK) is a high-performance thermoplastic often used in micro gear pump shafts. It combines excellent mechanical strength with outstanding chemical resistance. PEEK can handle a wide range of fluids, including those with harsh chemical properties, without degrading.

This material also performs well in high-temperature environments. Its lightweight nature reduces the overall weight of the pump, which can improve energy efficiency. PEEK is particularly useful in applications where both durability and chemical compatibility are critical.

Teflon

Teflon, also known as polytetrafluoroethylene (PTFE), is another material commonly used in micro gear pump shafts. It is highly resistant to chemicals, making it suitable for handling corrosive fluids. Teflon also has a low coefficient of friction, which minimizes wear and improves the pump’s efficiency.

One of the unique properties of Teflon is its non-stick surface. This feature prevents fluid buildup on the shaft, ensuring smooth operation. However, Teflon is not as strong as other materials like stainless steel or PEEK, which limits its use in high-stress applications.

Factors Influencing Shaft Material Selection

Mechanical Properties

The mechanical properties of a shaft material determine its ability to handle stress and strain during operation. Materials with high tensile strength resist deformation under heavy loads. Hardness plays a key role in reducing wear caused by friction between moving parts.

Elasticity is another critical factor. A shaft material must flex slightly without breaking to absorb shocks during operation. Choosing a material with balanced mechanical properties ensures the micro gear pump performs reliably under varying conditions.

Corrosion Resistance

Corrosion resistance is vital for shafts exposed to fluids with chemical properties. Materials that resist rust and chemical degradation maintain their structural integrity over time. Stainless steel and ceramic excel in environments with corrosive substances.

A shaft with poor corrosion resistance can weaken and fail prematurely. Protective coatings, such as plating or polymer layers, enhance the resistance of materials like carbon steel. Selecting a corrosion-resistant material ensures the pump operates efficiently in challenging environments.

Temperature Resistance

Temperature resistance affects a shaft’s performance in high-heat or low-temperature conditions. Materials like ceramic and PEEK withstand extreme temperatures without losing their mechanical properties.

Thermal expansion is another consideration. A shaft material must maintain dimensional stability to prevent misalignment of gears. For micro gear pumps handling hot fluids, temperature-resistant materials ensure consistent operation and prevent damage.

Cost vs. Durability

Cost and durability often influence material selection. While high-performance materials like ceramic and PEEK offer exceptional properties, they come at a higher price. Stainless steel provides a balance between cost and durability, making it a popular choice for many applications.

Choosing the right material involves evaluating the application’s demands and budget constraints. A cost-effective yet durable material ensures the micro gear pump delivers reliable performance without excessive expenses.

How to Choose the Right Shaft Material for Your Application

- High-viscosity fluids require a shaft material with excellent mechanical strength to handle the increased stress. For fluids with aggressive chemical properties, materials like stainless steel, ceramic, or PEEK offer superior chemical resistance.

- High-temperature applications demand materials like ceramic or PEEK, which maintain their properties under extreme heat. For high-pressure systems, materials with high tensile strength, such as stainless steel, are ideal.

- Exposure to chemicals also influences material choice. Shafts operating in harsh chemical environments benefit from corrosion-resistant materials. For instance, stainless steel resists rust, while ceramic withstands aggressive chemicals. Evaluating these factors ensures the micro gear pump operates reliably in its intended environment.

- Cost is a critical factor when selecting a shaft material. While high-performance materials like ceramic or PEEK may have a higher upfront cost, they often reduce maintenance and replacement expenses over time. Stainless steel offers a balance between cost and durability, making it a popular choice for many applications.

Common Issues with Incorrect Material Selection

Wear and tear

A shaft made from a soft material may wear out faster when used in high-torque applications. This wear reduces the efficiency of the micro gear pump and increases maintenance needs. Over time, the friction accelerates damage and shortens the pump’s lifespan. Selecting a material with the right mechanical properties minimizes wear and ensures reliable operation.

Impact of Material corrosion and fatigue

Corrosive fluids or chemicals can weaken shaft materials, leading to structural failure. Fatigue occurs when a shaft experiences repeated stress cycles. Over time, this can cause cracks or fractures, especially in materials with low fatigue resistance.

Pump Failure

A shaft that cannot withstand the operating environment may misalign the gears, disrupting fluid flow. This misalignment increases wear on other components, leading to a chain reaction of failures. In extreme cases, a shaft may break under stress, rendering the pump inoperable. Selecting the right material ensures the pump operates efficiently and avoids costly downtime.

Conclusion

Choosing the right material for a micro gear pump shaft is essential for ensuring optimal performance. Stainless steel, ceramic, PEEK, and Teflon each offer different advantages based on the application’s needs—whether it’s corrosion resistance, temperature tolerance, or mechanical strength. For reliable, high-quality micro gear pumps, trust CHENHUI to provide the ideal materials for your requirements.