Gear pumps play a vital role in industries requiring the transfer of fluids. These pumps deliver precise and consistent flow rates, making them a reliable choice for tasks like lubrication and chemical processing.

However, they cannot handle solids or abrasive materials, which limits their applications. Understanding gear pump advantages and disadvantages helps users determine if these pumps meet their specific needs.

What is a Gear Pump

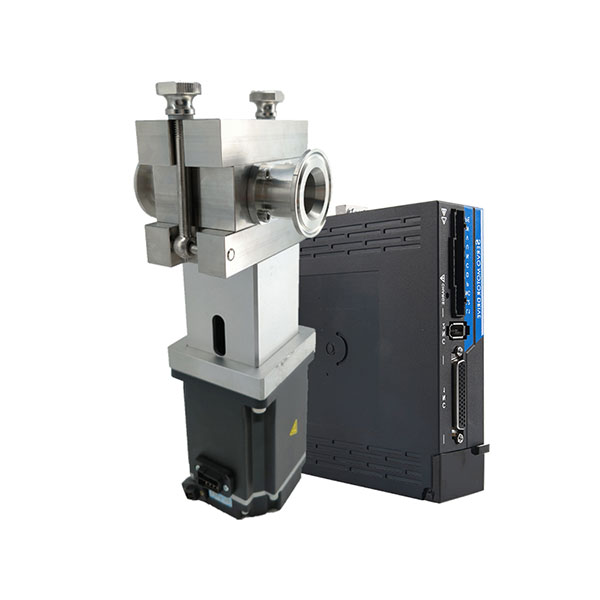

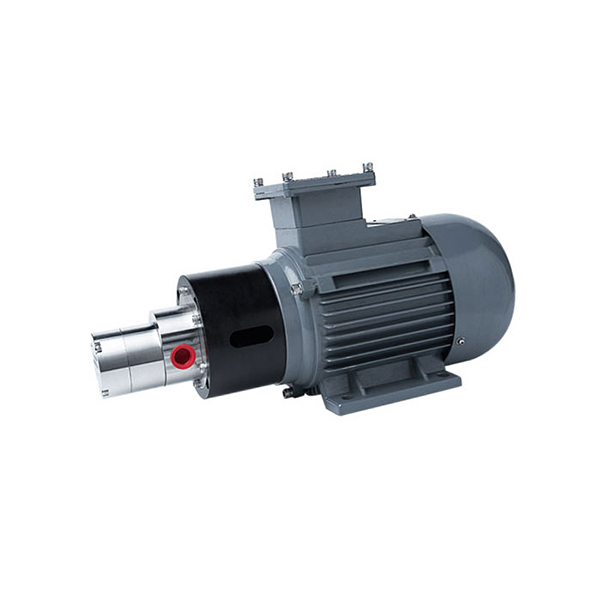

Definition and Working Principle

A gear pump is a type of positive displacement pump that moves fluids by trapping them between rotating gears. It operates by creating a vacuum at the pump inlet, which draws fluid into the gear chamber.

As the gears rotate, they transfer the fluid along the outer edges of the chamber to the outlet. This process ensures a steady and consistent flow of liquid.

The pump’s design typically includes two gears: a driving gear and a driven gear. These gears mesh together, forming tight clearances that prevent fluid from flowing backward. This mechanism makes gear pumps highly efficient for transferring liquids, especially those with high viscosity.

Advantages of Gear Pumps

High Efficiency and Energy Savings

Gear pumps are known for their high efficiency, as they operate with minimal fluid leakage due to tight gear clearances. This design ensures energy is used effectively, reducing operational costs.

Their consistent pressure and flow mean less additional energy is needed, leading to further cost savings. Additionally, gear pumps maintain performance when handling high-viscosity fluids, ensuring smooth operation without excessive energy consumption.

Smooth and Consistent Fluid Flow

Gear pumps provide steady, uninterrupted fluid flow, making them ideal for applications requiring precision, such as chemical dosing or lubrication systems.

The meshing gears create uniform flow, eliminating pulsations and ensuring reliable performance in industries like food processing or hydraulics, where consistent fluid delivery is critical.

Compact and Space-Saving Design

These pumps have a compact, lightweight design, making them easy to install in space-constrained systems. Despite their small size, they deliver high efficiency and reliable operation, which is particularly beneficial in mobile hydraulic systems or small-scale industrial setups.

Low Maintenance Requirements

Gear pumps require minimal maintenance due to their simple design and fewer moving parts. Routine checks, such as ensuring proper lubrication and inspecting seals, are typically sufficient to keep the pump running smoothly, saving time and resources on upkeep.

Self-Priming Capability

Gear pumps can prime themselves without external assistance. The tight clearances between the gears create a vacuum, drawing fluid into the pump chamber.

This self-priming feature eliminates the need for pre-filling, saving time and ensuring reliable performance, even during intermittent operation.

Ability to Handle High-Viscosity Fluids

Gear pumps excel at transferring high-viscosity fluids like oils, syrups, and adhesives. Their positive displacement mechanism ensures consistent performance, even with thick liquids.

Unlike centrifugal pumps, which struggle with such fluids, gear pumps maintain steady pressure and flow, making them a reliable choice for industries such as food processing, chemical manufacturing, and lubrication systems.

Disadvantages of Gear Pumps

Limited Fluid Compatibility

Gear pumps are not suitable for handling abrasive or corrosive fluids. Abrasive particles can wear down the gears and seals, leading to reduced efficiency and increased maintenance.

Corrosive liquids can damage the pump’s internal components, significantly shortening its lifespan. Careful evaluation of the fluid’s composition is essential before choosing a gear pump for specific applications.

Wear and Tear

The tight tolerances within gear pumps can result in internal leakage and wear over time. As components degrade, the pump’s efficiency decreases, requiring more frequent repairs or replacements.

Regular maintenance and the use of compatible fluids can help mitigate this issue, but it is still a concern for long-term operation.

Limited Pressure Capabilities

Although gear pumps are reliable for moderate pressures, they are not designed for high-pressure applications. For applications requiring higher pressure, alternative pumps like piston pumps are more effective.

If you need to handle extreme pressure conditions, gear pumps may not be the best solution.

Fixed Flow Rate

Gear pumps typically offer a fixed flow rate, making them less versatile when varying flow rates are required. This lack of flexibility can be limiting in applications where fluid transfer needs to be adjusted dynamically. Other pump types with adjustable flow rates may be more suitable for such tasks.

Inability to Run Dry

Gear pumps should not be operated dry for extended periods, as this can damage the internal components due to a lack of lubrication.

This is particularly important in applications where the pump might temporarily run without fluid, as it can lead to costly repairs or premature pump failure.

Factors to Consider When Choosing a Gear Pump

When selecting a gear pump, there are key factors to consider including:

- Flow Rate: The volume of fluid the pump can handle, directly influencing its ability to meet specific application demands.

- Pressure Requirements: Ensure the pump can handle the required pressure without causing excessive wear or damage.

- Fluid Viscosity: The pump’s suitability for the fluid’s viscosity is critical for optimal performance. High-viscosity fluids may require specific pump designs.

- Power and Efficiency: Consider the pump’s power requirements and efficiency to ensure it operates effectively and minimizes energy consumption.

- Operating Temperature: Select a pump that can handle the temperature range of the fluid without compromising performance or durability.

- Material Compatibility: The materials used in the pump must be compatible with the fluid being transferred, especially in cases involving corrosive or abrasive substances.

- Durability and Maintenance: Choose a pump designed for longevity and ease of maintenance, especially for high-demand or harsh operating conditions.

- Size and Space Constraints: Ensure the pump fits within the available space in your system, considering its compactness and design.

Common Applications of Gear Pumps

Gear pumps are versatile and widely used across various industries due to their reliability and efficiency in handling specific fluid transfer needs. Some key applications of gear pumps include:

- Automotive Industry: Gear pumps are used in automotive engines to provide lubrication for engine components and in fuel injection systems to ensure consistent fuel delivery.

- Chemical Processing: They are ideal for transferring chemicals, solvents, and viscous liquids, where precise dosing and consistent flow rates are critical.

- Oil and Gas Industry: Gear pumps play a crucial role in transporting lubricants, and refined products, as they can handle both high-viscosity and irregularly supplied fluids efficiently.

- Food and Beverage Industry: Gear pumps are essential in transferring syrups, oils, sauces, and other food-grade liquids. Their ability to handle thick and viscous fluids makes them ideal for such applications.

- Pharmaceuticals: They are used to produce and transfer medicinal liquids, active pharmaceutical ingredients (APIs), and other critical ingredients in the production process, where hygiene and precise flow control are necessary.

Conclusion

Gear pumps are reliable and efficient for fluid transfer in many industries, especially when handling high-viscosity liquids. While they offer significant advantages like consistent flow and low maintenance, their limitations, such as wear from abrasive fluids and fixed flow rates, should be considered when selecting the right pump for specific applications.