In the field of fluid handling, precision, leak – proof performance, and durability are crucial factors. The micro magnetic gear pump stands out as a game – changer, offering unmatched advantages for a wide range of industrial and laboratory applications. Whether you are in the pharmaceutical, chemical, food and beverage, or electronics industry, this innovative pump can meet your most demanding fluid transfer needs.

What Makes Micro Magnetic Gear Pumps Unique?

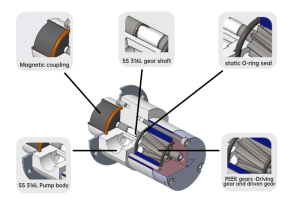

Unlike traditional gear pumps, the micro magnetic gear pump uses a magnetic drive system instead of a mechanical seal. This design eliminates the risk of leaks, which is a common problem with mechanical seals, especially when handling corrosive, toxic, or high – value fluids. The magnetic coupling ensures a hermetic seal, preventing fluid loss and protecting the environment and operators from potential hazards.

Another key feature of the micro magnetic gear pump is its compact size. Despite its small footprint, it delivers high precision and consistent flow rates. The micro – sized gears are engineered to handle low to medium viscosity fluids with extreme accuracy, making it ideal for applications that require precise metering, such as drug delivery in pharmaceutical manufacturing or ink transfer in printing processes.

Durability is also a strong suit of the micro magnetic gear pump. The gears and other critical components are made from high – quality materials like stainless steel, ceramic, or PEEK (Polyether Ether Ketone), which are resistant to corrosion, wear, and high temperatures. This ensures a long service life and minimal maintenance, reducing operational costs for businesses.

Key Applications of Micro Magnetic Gear Pumps

- Pharmaceutical Industry: Used for precise dosing of drugs, vaccines, and other pharmaceutical ingredients. The leak – proof design ensures product purity and compliance with strict industry regulations.

- Chemical Industry: Ideal for transferring corrosive chemicals, solvents, and reagents. The chemical – resistant materials prevent degradation of the pump and contamination of the fluid.

- Food and Beverage Industry: Suitable for handling food additives, syrups, and essential oils. The sanitary design meets food safety standards, ensuring no cross – contamination.

- Electronics Industry: Used in the production of semiconductors and electronic components, where precise fluid transfer is essential to avoid defects.

Why Choose Our Micro Magnetic Gear Pumps?

Our micro magnetic gear pumps are designed and manufactured to the highest standards, ensuring reliable performance and long – term durability. We use advanced materials and manufacturing processes to create pumps that can withstand harsh operating conditions, while delivering precise and consistent flow rates.

In addition, we offer a wide range of customization options to meet the specific needs of our customers. Whether you need a pump with a specific flow rate, pressure rating, or material compatibility, our team of experts can work with you to design a solution that fits your requirements.

We also provide excellent after – sales service, including technical support, maintenance, and repair services. Our goal is to ensure that our customers get the most out of their micro magnetic gear pumps, and we are committed to providing the highest level of customer satisfaction.

If you are looking for a high – performance, reliable, and cost – effective fluid transfer solution, look no further than our micro magnetic gear pumps. Contact us today to learn more about our products and how they can benefit your business.